What is Vertical Packaging Machine for Seeds?

Vertical Packaging Machine for Seeds is an automated packaging equipment designed specifically for the seed industry. It can efficiently complete the entire process of metering, bag making, filling, sealing, and printing dates. It is suitable for a variety of granular materials such as rice, wheat, and vegetable seeds. The packaging speed is up to 150 bags/minute, meeting the needs of different production scales. Its metering range is usually 1-1500 grams or 150-2000 milliliters, ensuring that the weight or quantity of each package of seeds is accurately controllable. The packaging bag type is flexible and can be made into pillow bags or perforated hanging bags to adapt to different sales scenarios. The bag size range is wide, with a length of 80-300 mm and a width of 80-200 mm. Users can adjust the packaging specifications according to the type of seeds. The equipment uses imported PLC and touch screen control systems, which are easy to operate and have functions such as automatic deviation correction and intelligent temperature control to ensure a firm and beautiful seal. In addition, the machine is compatible with a variety of packaging materials (such as OPP/CPP, PET/PE and other composite materials), and supports customized functions such as date printing, batch number marking, etc., which are suitable for farms, seed companies and other scenarios, significantly improving packaging efficiency and quality.

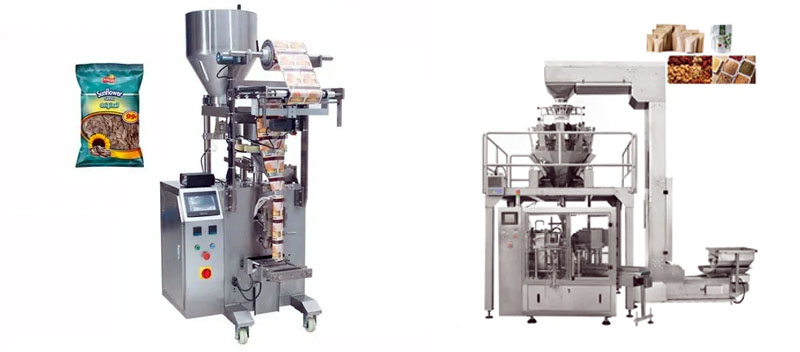

What types of Vertical Packaging Machine for Seeds are there?

Vertical Packaging Machine for Seeds can be divided into small, medium, large and customized models according to seed types and packaging requirements.

| Model | Applicable seed type | Packing size (length × width) | Packing speed | Applicable scenarios |

| Small seed packaging machine (MC5000D) | Small grain seeds (vegetables, flowers, etc.) | 50~280mm × 70~180mm | 25~80 bags/minute | Small batch, high-precision packaging requirements |

| Medium-sized seed packaging machine (MC5000B) | Medium-grain seeds (rice, wheat) | 50~340mm × 80~250mm | 10~50 bags/minute | Medium-scale production, general packaging |

| Large-scale seed packaging machine (MC7300B) | Large-grain seeds (corn, soybeans) | 50~460mm × 80~350mm | 10~50 bags/minute | Large particles or high-capacity packaging requirements |

| Customized seed packaging machine (MC1100) | Ultra-large bag seeds (5kg~15kg) | 300~650mm × 300~535mm | 10~50 bags/minute | Wholesale, warehousing and other large-scale packaging scenarios |

What are the advantages of Vertical Packaging Machine for Seeds?

Vertical Packaging Machine for Seeds has fast packaging speed and accurate measurement, which is suitable for diversified packaging.

Specialized seed packaging design: moisture-proof sealing design to ensure that seeds are not damp during storage, anti-static treatment to prevent small-particle seeds from sticking, gentle feeding system to protect seed germination rate from damage, transparent window design to facilitate seed quality inspection.

High-precision measurement: high-precision weighing sensor and electronic scale are used for measurement, and the measurement accuracy can reach ±0.2%, ensuring that the weight of each package of seeds is accurate. For small-particle seeds (such as rice and vegetable seeds) that pay special attention to quantity consistency, the equipment can also be configured with a counting function to achieve accurate quantity packaging.

High-speed packaging: up to 150 bags/minute, which is more than 10 times the efficiency of manual packaging. A fully automatic seed packaging machine can replace 8-10 packaging workers, significantly reducing labor costs.

Diversified packaging: supports multiple packaging types such as back sealing, three-side sealing, four-side sealing, etc., and can be matched with a variety of packaging films such as PE, PP, aluminum foil, etc. to meet different seed packaging needs.

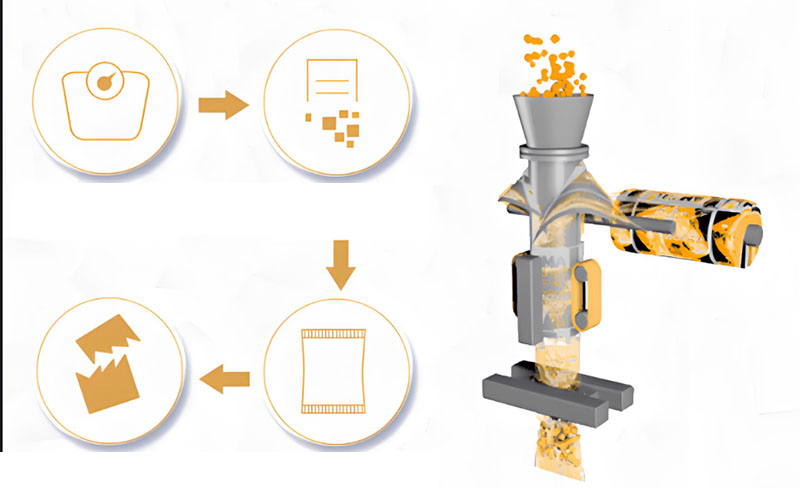

What is the principle of Vertical Packaging Machine for Seeds?

Vertical Packaging Machine for Seeds completes the packaging operation through a highly automated process. First, the seeds are sent into the feed bin by a hoist or manually, and then transported to the metering device by vibration, spiral or belt, and accurately measured by weighing, volume and other different metering methods; then the packaging film is made into bags and filled with seeds, and the transverse heat sealer is sealed and cut; finally, the finished product is output and can be connected to subsequent equipment. The PLC control system coordinates all links, and the servo motor drives, with accurate positioning and adjustable speed.

Vertical Packaging Machine for Seeds parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of Vertical Packaging Machine for Seeds?

The seed vertical packaging machine is widely used in various types of crop seed packaging operations. Whether it is grain crop seeds such as rice and wheat, economic crop seeds such as cotton and rapeseed, or vegetable seeds such as leafy vegetables, fruit and vegetables, as well as grass and flower bulbs, flower seeds, and even special seeds such as medicinal materials, trees, and forage, it can respond accurately. According to the characteristics of different seeds, we provide diversified packaging specifications, speeds and metering methods, equipped with special feeding systems and targeted designs to meet the packaging needs of seeds of different weights and shapes from 1-25kg.

![[field:title/]](/uploads/250614/1-250614152955505.jpg)