What is high speed packaging machine?

High speed packaging machines are automated equipment designed to complete the packaging process quickly and efficiently. They can complete a large number of packaging needs in a short period of time, with a speed of up to 200 packages per minute or more. Compared with traditional packaging methods, high-speed packaging machines can improve production efficiency while maintaining the accuracy of weighing, sealing and labeling.

High speed packaging machines are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods, where high production volumes and efficiency are crucial. By combining speed, precision, and automation, these machines enable manufacturers to achieve rapid and reliable packaging operations to meet market demands.

What are the features of High Speed Packaging Machine

The core advantage of High Speed Packaging Machine is its extremely fast packaging speed, which is suitable for large-scale production line needs:

Ultra-high-speed packaging capability

Food industry: granule packaging can reach 150 bags/minute, liquid packaging can reach 160 bags/minute.

Pharmaceutical industry: Blister-pillow packaging-cartoning machine can achieve high-speed production of 600 boards/minute.

Candy/chocolate packaging speed reaches 300 pieces/minute.

Highly automated: Automatically complete feeding, metering, bag making, sealing, slitting and other processes, reduce manual intervention, and improve packaging accuracy and consistency.

Save labor costs: One high speed packaging machine can replace multiple workers, reduce labor costs, and adapt to modern production needs.

How does high speed packaging machine work?

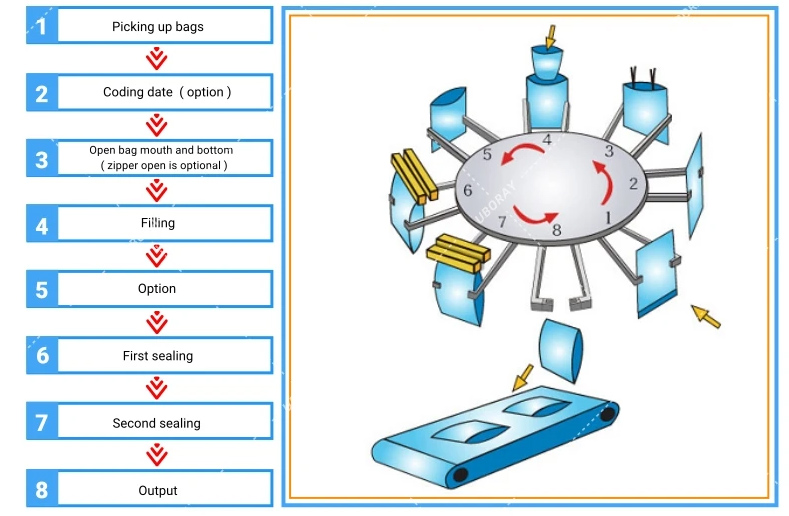

The high speed packaging machine is an efficient packaging equipment, and its working principle is based on the following steps: First, granular or powdery products are continuously fed to the vertical packaging machine through the feeding system. The machine then automatically completes the bag forming, filling, sealing and cutting steps. During the filling stage, a precise metering system fills the product accurately into the bag. Next, the bag is sealed via heat sealing or other sealing techniques to ensure the product remains fresh and enclosed. Finally, the packed bags are cut and discharged, ready for the next round of packaging.

Live video

High speed packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

How to choose a high-speed packaging machine?

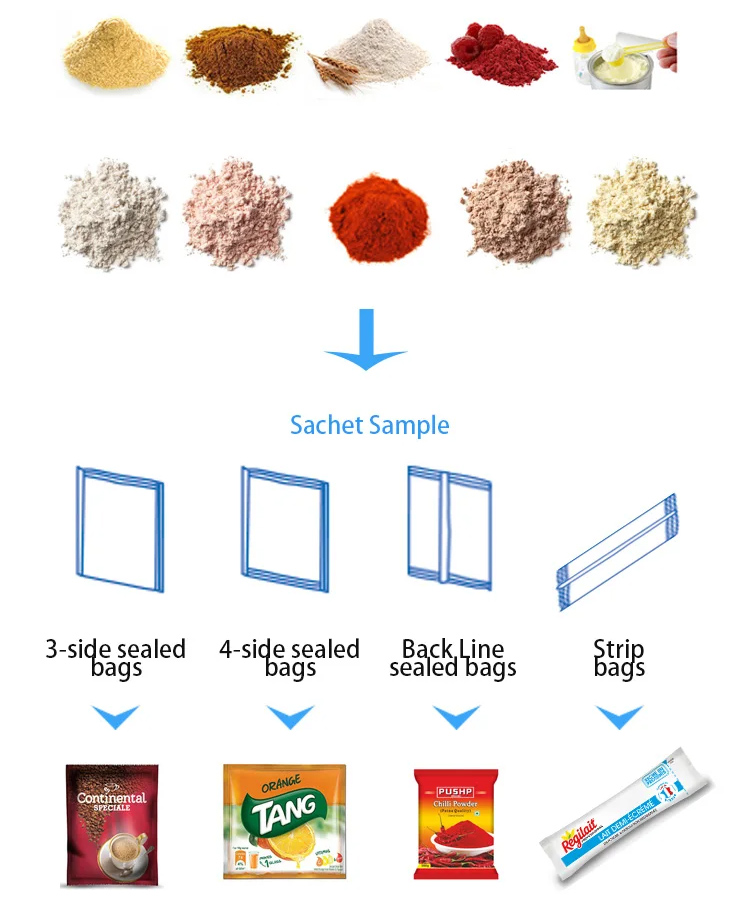

The high speed packaging machine can be used for different packaging materials and packaging types, depending on the characteristics of the product and industry needs. Here are some common packaging materials and packaging types:

Packaging materials

| Material type | Example | Main application areas |

| Plastic film | Polyethylene (PE), polypropylene (PP), polyester (PET) | Food, beverages, daily necessities, etc. |

| Paper and paperboard | Kraft paper, corrugated paperboard | Food, medicine, cosmetics, electronic products, etc. |

| Metal materials | Aluminum foil, tinplate | Food preservation, anti-oxidation packaging |

| Glass | Glass bottles, glass jars | Beverages, food, cosmetics and other high-end products |

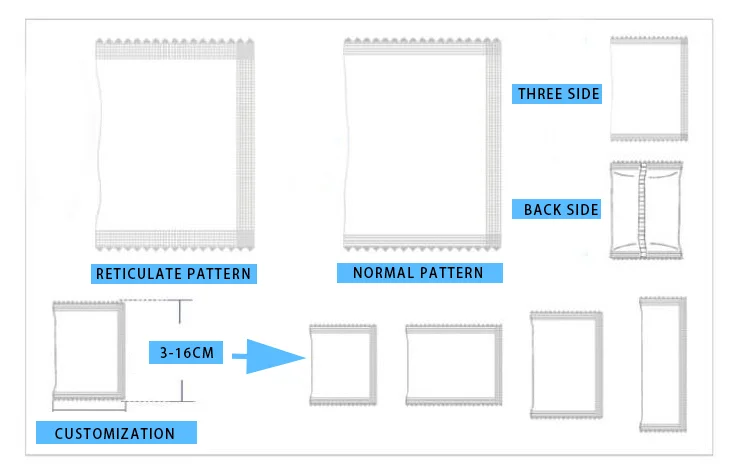

Packaging bag size

| Packaging type | Size range (length × width × height) | Typical applications |

| Particle/powder bags | 30–180mm × 20–75mm × 5–68mm | Food, chemical products |

| Liquid bags | 20–140mm × 20–110mm | Beverages, condiments |

| Small bags | 40–90mm × 30–90mm | Small packaged food, medicines |

| Big bags | 40–125mm × 30–110mm | Large packaged food, industrial products |

| Big bags/ton bags | 25kg–2 tons/bag | Bulk materials, industrial raw materials |

Packaging type

| Type | Description | Applicable products |

| Bagged packaging | Woven bags, three-dimensional bags, etc. | Granular, powder, liquid products |

| Bottle packaging | Plastic bottles, glass bottles, etc. | Liquid, powder, granular products |

| Boxed packaging | Paper boxes, gift boxes, etc. | Food, electronic products, gifts |

| Vacuum packaging | Remove air from the packaging | Food, medicines, and other products that need to be kept fresh |

| Canned packaging | Metal cans, glass jars, etc. | Food, beverages, cosmetics, etc. |

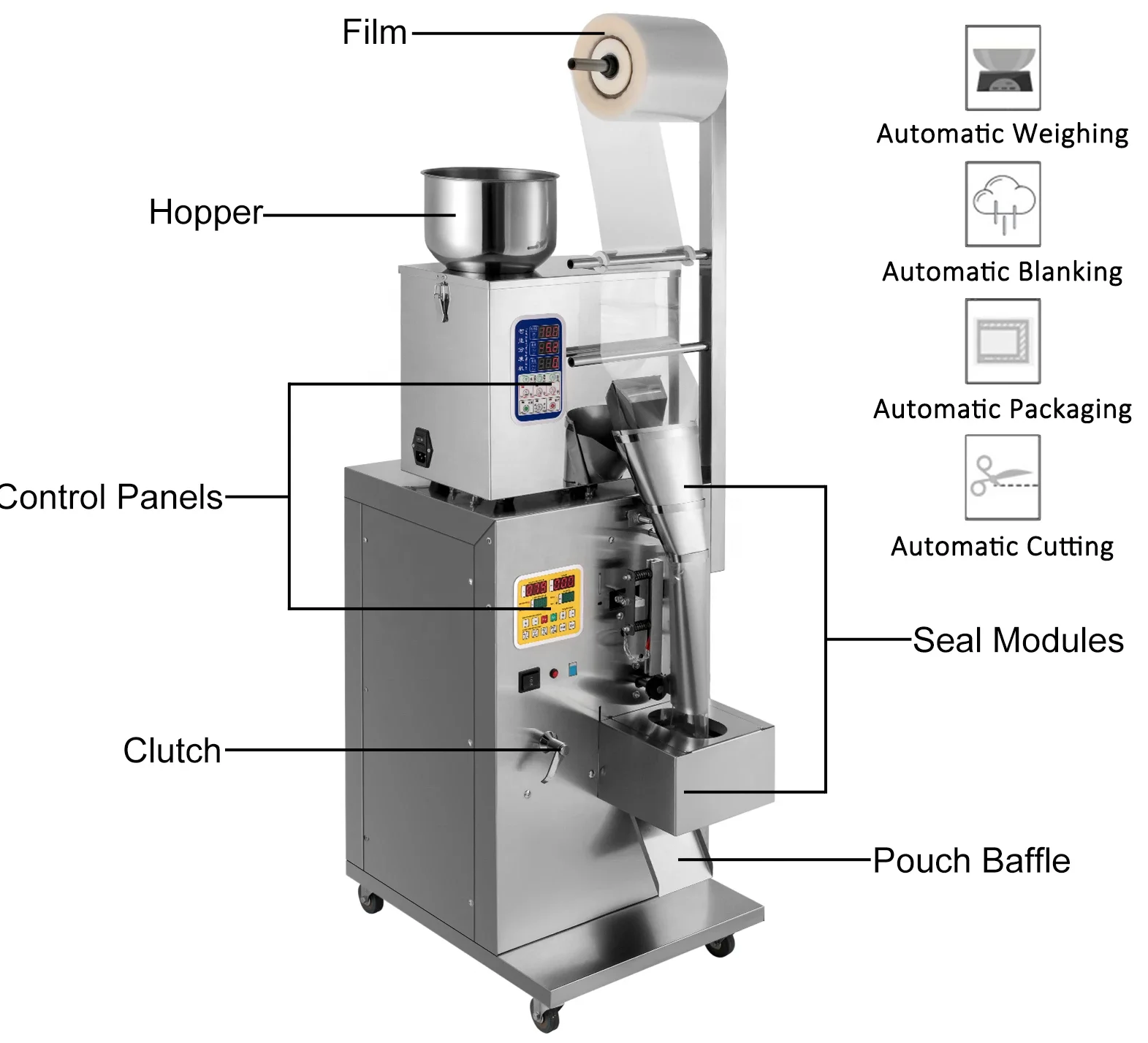

Structure of high speed packaging machine

High-speed packaging machines usually consist of a feeding system, a metering system, a vertical packaging tube, a sealing system and a control system. The product enters the vertical packaging tube through the feeding system, is accurately measured by the metering system during operation, and then enters the packaging bag through vertical descent. The sealing system is responsible for sealing the packaging bag and can be cut or otherwise processed as needed. The control system is used to monitor and control the operation of the packaging machine, including adjusting parameters, setting packaging specifications, and monitoring operating status.

Difference between high speed packaging machine and ordinary packaging machine

| Difference | High Speed Packaging Machine | Ordinary Packaging Machine |

| packaging speed | The packaging speed has exceeded the traditional level and reached 3,600 packages per minute. It is more than 10% higher than traditional products. | Packaging speed can vary depending on product and bag size, usually between 2,000 bags per hour |

| Capacity | Have higher throughput, allowing them to handle larger quantities of products in a given time frame. | Lower throughput |

| Automation and Efficiency | Enable precise and efficient handling, filling, sealing and labeling processes to minimize downtime and maximize productivity. | The function is relatively simple and the level of automation is not high |

| flexibility | Can accommodate various types of packaging including bags, pouches, cartons, bottles, etc., providing a wider range of product packaging options. | Packaging form is relatively limited |

What are the applications of High Speed Packaging Machine?

High Speed Packaging Machine can quickly and accurately package a variety of granular, powdered and liquid products.

Food and Beverage: Snacks, beverages, candies, biscuits, puffed foods, nuts, rice and flour products, etc. can be packaged quickly to improve production efficiency..

Pharmaceuticals: Used for packaging pharmaceuticals such as pills, tablets and capsules.

Cosmetics: Used for packaging cosmetics, such as cosmetics, skin care products, perfumes, etc.

Electronics: Used for packaging electronics such as smartphones, tablets, and laptops.

Industrial products: used for packaging industrial products, such as hardware, tools, mechanical parts, etc.

Customer case

Below are some customer cases of high-speed packaging machines. These cases are for demonstration purposes only. Actual customer cases may vary depending on the industry and specific requirements.

| Client's Name | Packaging Products | type of packaging | Packaging Materials | Packaging volume (per minute) |

| Indonesia ** Food Co., Ltd. | Spices | Bagged | Plastic bag | 500 |

| Canada ** Pharmaceutical Co., Ltd. | Pharmaceutical liquid | Bottled | Glass bottle | 800 |

| American** Beverage Group | Drinks | Canned | Metal can | 1200 |

| Australia's ** cosmetics company | Cosmetic | Boxed | Carton | 600 |

| India ** Electronics Ltd. | Screw | Packing | Carton | 300 |

| France ** Medical Equipment Co., Ltd. | Medical sterile swab | Bagged | Medical plastic bags | 1000 |

High Speed Packaging Machine Manufacturers

Xinxiang Dahan high speed packaging machine manufacturer has rich experience and professional knowledge and has a good reputation in the field of high-speed packaging machines. Their machines use advanced technology and innovative designs to enable efficient, precise and reliable packaging. They focus on quality control to ensure product stability and reliability. In addition, they offer customized solutions to meet customers' specific packaging needs. In short, Xinxiang Dahan high-speed packaging machine manufacturer stands out in the industry for its professionalism, reliability and flexibility.