What is liquid and paste packaging machine?

Liquid and paste packaging machine is a specialized equipment designed to automatically package liquid and paste products. It is commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. This machine is capable of accurately measuring, filling, sealing, and labeling liquid and paste substances into various types of packaging containers such as bottles, pouches, tubes, and jars. It ensures efficient and consistent packaging, improves production speed, and maintains the integrity and quality of the products. The machine can be customized to meet specific requirements, including different packaging sizes, shapes, and materials.

What is the difference between liquid and paste packaging machine?

| Classification | Liquid packaging machine | Paste packaging machine | Applicable materials | Liquids with high fluidity, such as water, milk, juice, soy sauce, alcohol, detergent, etc. | Paste materials with high viscosity or particles, such as ketchup, honey, jam, cream, shampoo, lotion, etc. |

| Filling method | Use pump filling (such as magnetic pump, plunger pump) to ensure accurate metering, suitable for flowing liquids. | Use piston pump or screw pump filling, equipped with stirring and heating devices, suitable for high viscosity or particle-containing materials. |

| Packing speed | Generally 10-80 bags/minute, depending on the nature of the material and the model of the equipment. | Usually 24-60 bags/minute, the speed is affected by the viscosity of the material and the size of the packaging bag. |

| Packing capacity | 5ml-1000ml, suitable for small bag packaging. | 5ml-5000ml, suitable for small bags to large bags. |

| Packaging form | Back seal, three-side seal, four-side seal and other bag types. | Back seal, three-side seal, four-side seal, stick bag, continuous bag and other diversified bag types. |

| Structural features | Compact structure, easy operation, suitable for high-speed packaging of flowing liquids. | Equipped with stirring and heating system, suitable for high-viscosity materials, ensuring uniform filling. |

Live shooting of packaging machine working

How does liquid and paste packaging machine work?

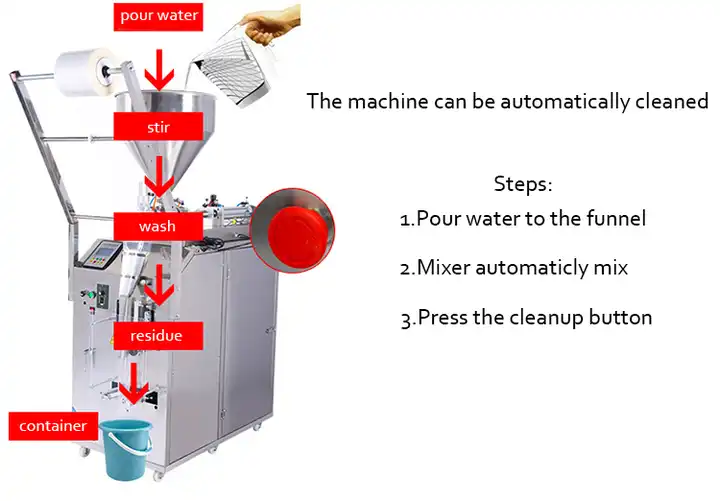

A liquid and paste packaging machine operates by automatically filling, sealing, and labeling liquid and paste products into various packaging containers. The machine uses precise metering systems to measure the desired amount of liquid or paste product, which is then dispensed into the packaging container. The container is then sealed using techniques such as capping, heat sealing, or induction sealing to ensure product freshness and prevent leakage. Finally, the machine applies labels or prints batch information on the packaging for identification and traceability purposes.

Liquid & paste packaging machine specifications

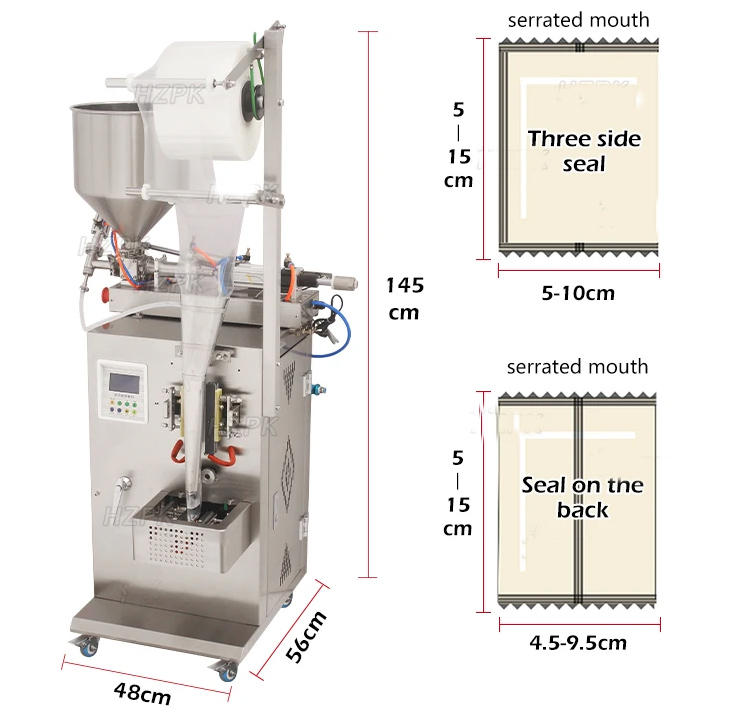

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of liquid & paste packaging machine

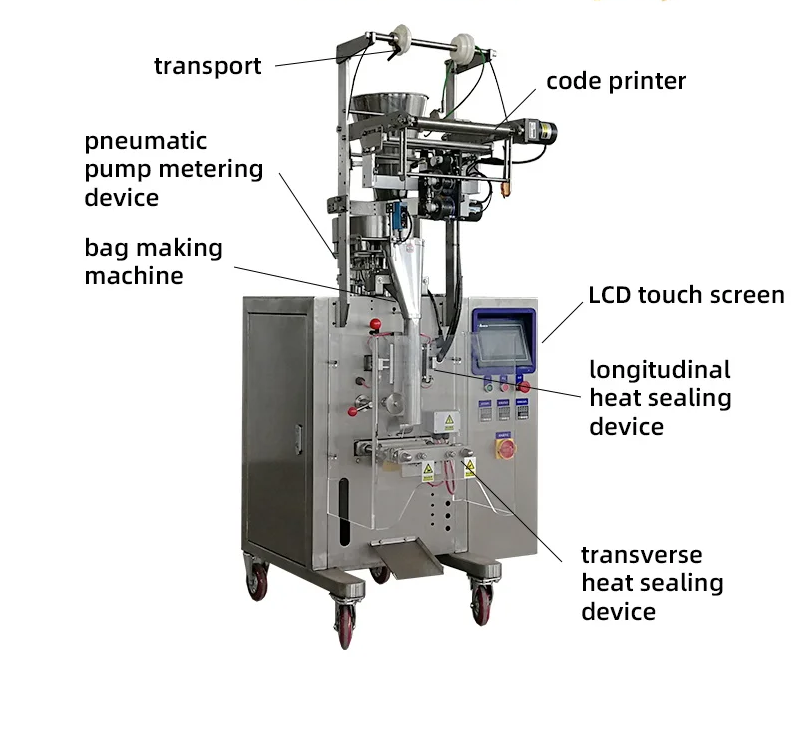

Liquid and paste packaging machines typically consist of several key components that work together to facilitate the packaging process. These components include a container feeding system, a filling system, a sealing system, a labeling/coding system (optional), and a control system. The container feeding system can be manual or automated, and it transports empty containers to the filling station. The filling system accurately dispenses the liquid or paste product into the containers using volumetric, piston, or gravity-based mechanisms. The sealing system ensures a secure and leak-proof seal on the containers, employing methods such as heat sealing or ultrasonic sealing. Optional labeling and coding systems can apply labels or codes to the containers for product identification and traceability. The control system, often based on programmable logic controllers (PLCs), manages and monitors the machine's operation, controlling the filling quantity, sealing parameters, and overall packaging process. The combination of these components enables efficient and reliable packaging of liquid and paste products.

What are the advantages of different liquid and paste packaging machines?

We have 6 types of liquid and paste packaging machines to choose from, each of which can adapt to different product requirements and packaging forms.

Ice cube packaging machine: With cooling system, it is suitable for bagging, sealing, printing date and other operations of ice cubes to ensure the quality and hygiene of ice cubes.

Fully automatic paste prefabricated bag packaging machine: Suitable for packaging various paste products, such as jam, peanut butter, etc., it can automatically complete filling, sealing and other operations to improve production efficiency.

Liquid special-shaped bag packaging machine: Specially designed for packaging liquid products such as beverages, seasonings, etc., adapting to bags of different shapes and sizes, providing flexible packaging solutions.

Ketchup liquid metering packaging machine: With precise metering function, it is suitable for packaging liquid products such as ketchup to ensure that the weight or volume of each packaging unit is accurate.

Fully automatic small bag soda water packaging machine: Designed for small bag packaging needs, it can automatically complete filling, sealing and other operations, suitable for small packaged beverage products such as soda water.

Salad mustard sauce automatic packaging machine: Designed for salad dressing, mustard sauce and other condiments, it realizes automatic packaging, sealing and other functions, improves production efficiency and ensures packaging quality.

What is the purpose of liquid and paste packaging machines?

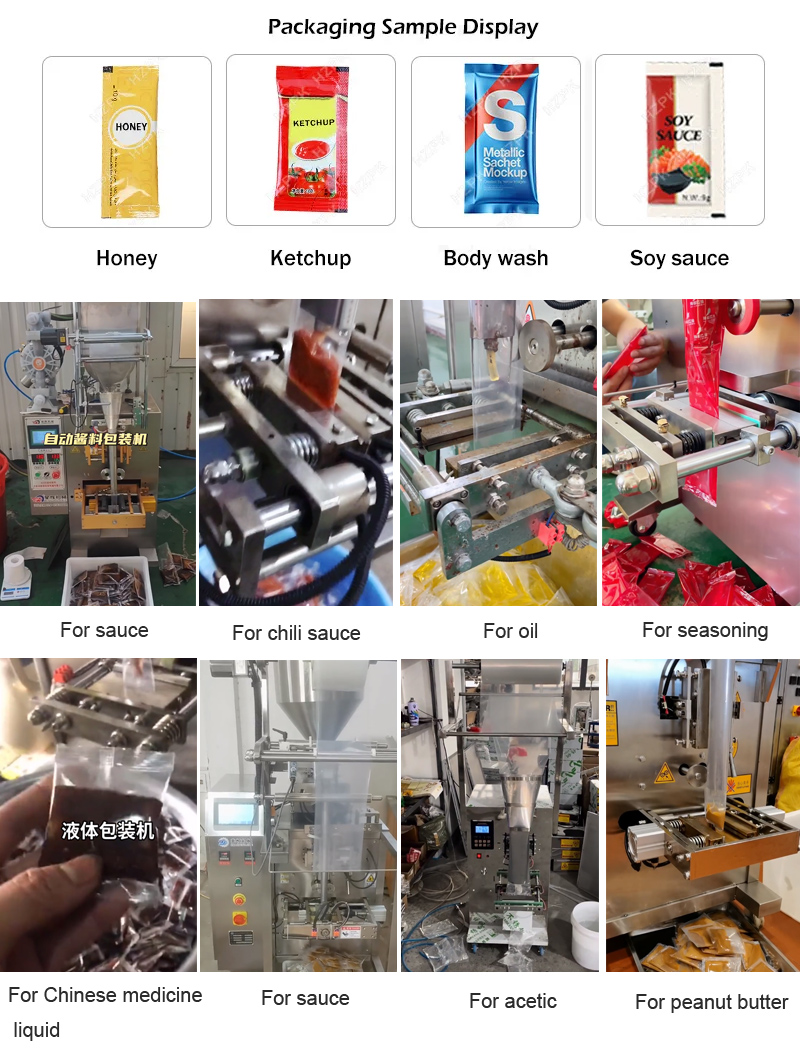

Liquid and paste packaging machine is widely used in food, medicine, cosmetics and other industries. It can automatically complete the packaging processes such as metering, filling and sealing of liquid and high-viscosity paste materials (such as sauces, jams, creams, shampoos, etc.), improve production efficiency, ensure packaging quality and extend product shelf life.

| Packaging Products | Purpose of Usage | Use Occasions |

| Drinks | Encapsulating and sealing liquids | Beverage production line, beverage factory |

| Shampoo | Fill and encapsulate shampoo | Cosmetic production line, personal care product factory |

| Edible oil | Filling and sealing edible oil | Food processing plants, supermarkets |

| Sauces | Filling and sealing sauce | Food production line, condiment factory |

Customer case

| Client's Name | Packaging Food | type of packaging | Packaging Materials | Packaging volume (per minute) |

| Philippines ** Beverage Co., Ltd. | drinks | bottled | PET plastic bottle | 1000 |

| Australian ** cosmetics company | cosmetic lotion | canned | aluminum can | 500 |

| Singapore ** Food Co., Ltd. | Sauces | bagged | Composite material bag | 800 |

| Czech** Pharmaceutical Co., Ltd. | ointment | tube | plastic pipe | 600 |

| Indian ** food group | edible oil | canned | glass bottle | 1200 |

| America's ** personal care products company | shampoo | bottled | HDPE plastic bottle | 1500 |

Liquid & Paste Packaging Machine price

Dahan Liquid Paste Packaging Machine is committed to providing high-quality and efficient packaging solutions to meet the packaging needs of customers for different types of products. We use the latest packaging technology and automated control systems to ensure that the packaging process is accurate and efficient. Regarding prices, we offer packaging machines in a variety of configurations and models. Prices vary depending on the model, function, and degree of customization, generally between $495.00-$8,800.00. We are committed to providing customers with competitive prices and high-quality after-sales service to help customers improve production efficiency, reduce costs, and achieve long-term win-win cooperation. If you are interested in our products or have any packaging needs, please feel free to contact us, and we will wholeheartedly provide you with the best packaging solutions.

Liquid & paste packaging machine manufacturers

Xinxiang Dahan is a manufacturer specializing in the manufacturing of liquid & paste packaging machines. They have many years of industry experience and technical expertise and enjoy a good reputation in the field of liquid and paste packaging machines. Xinxiang Dahan provides various types of liquid and paste packaging machines, including automatic filling machines, sealing machines, label attachment machines, etc., to meet the packaging needs of different industries and products. Their machines feature high precision, efficiency and reliability, using advanced control systems and processes to ensure accurate packaging and sealing of products. Xinxiang Dahan is committed to providing customers with high-quality packaging solutions and providing technical support and after-sales services to meet customer needs and establish long-term cooperative relationships.