What is Vertical Packaging Machine for Nuts?

Vertical Packaging Machine for Nuts is a fully automated packaging equipment designed for various nut products. It integrates metering, bag making, filling, sealing and printing, and realizes the automation of the whole process from raw materials to finished product packaging. It adopts advanced PLC control system and servo drive technology, and can efficiently handle various nut products from 10g small packages to 5kg large bags. Whether it is hard large-grain nuts such as macadamia nuts and walnuts, or fragile small particles such as pine nuts and melon seeds, it can achieve accurate metering and perfect packaging. The parts of the equipment that contact the materials are all made of 304/316 stainless steel or food-grade polymer materials, which fully comply with FDA and CE certification standards to ensure food safety and hygiene.

What types of Vertical Packaging Machine for Nuts are there?

According to the characteristics of nuts and packaging requirements, Vertical Packaging Machine for Nuts is mainly divided into three types: high-speed pillow type, precision weighing type and multi-functional self-supporting bag.

High-speed pillow-type Vertical Packaging Machine for Nuts: Suitable for regular nuts such as almonds, cashews, peanuts, etc., with a packaging speed of 60-180 bags/minute, using back-seal or gusseted bag type.

Precision weighing type Vertical Packaging Machine for Nuts: For high-value nuts such as pistachios, pecans, macadamia, etc., equipped with 10-bucket computer combination scale, the measurement accuracy is ±0.5%, avoiding the waste of precious raw materials.

Multifunctional self-supporting bag Vertical Packaging Machine for Nuts: Designed for daily nut mixed bags, it can handle dry and wet separated nuts and dried fruits at the same time, and supports high-end bag types such as zipper self-supporting bags and box bags.

What are the advantages of Vertical Packaging Machine for Nuts?

Vertical Packaging Machine for Nuts has high packaging efficiency and accurate measurement, intelligent detection and multi-material adaptability, hygienic standards and convenient production change.

Ultra-high packaging efficiency: The maximum speed can reach 250 bags/minute (depending on the model), which is more than 20 times more efficient than manual packaging, greatly reducing labor costs.

Precision metering system: imported high-precision weighing sensors are used to automatically adjust for nuts of different densities to ensure that the weight of each package is consistent, and the error is controlled within ±1%.

Wide material adaptability: It can handle a variety of packaging materials such as PE composite film, aluminum foil film, and aluminized film to meet the preservation and display needs of different nuts.

Intelligent detection function: It has intelligent detection systems such as no bag without material, incomplete bag opening without filling, and abnormal sealing alarm to reduce nut waste.

What is the principle of Vertical Packaging Machine for Nuts?

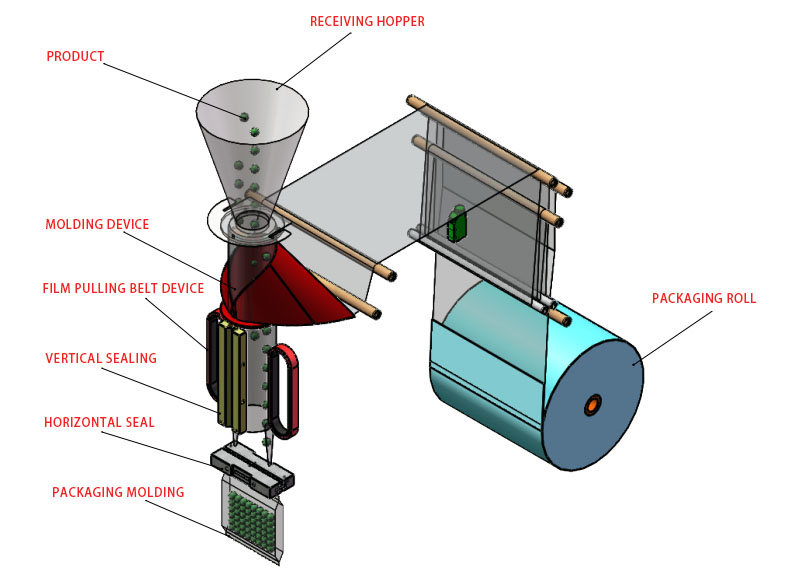

Vertical Packaging Machine for Nuts uses the integrated technology of "forming - filling - sealing". First, the roll film is rolled into a cylinder by the former and completed longitudinal sealing. Then the transverse sealing mechanism is heat-sealed and cut at the predetermined position to form the bottom of the bag; then, the computer combination scale or volumetric metering device accurately and quantitatively puts nuts, and the top is heat-sealed and cut after filling to form the package; finally, the finished product is sent out by the conveyor belt, and it can also connect to subsequent equipment such as metal detection and weight sorting to achieve a coherent and efficient packaging process.

Vertical Packaging Machine for Nuts parameters

| Parameters | XY-520 Model | MG150 Model | SmartPacker CX250-S4 |

| Packing Speed | 30-60 Packs/Minute | ≤100 Packs/Minute | Up to 250 Packs/Minute |

| Measuring range | 10-5000g | 1-1500g | Maximum 300g |

| Bag size | L100-350mm W80-250mm | L30-160mm W30-130mm | Width 70-250mm |

| Measuring accuracy | ±0.5%-±2% | ±1g | ±0.5% |

| Power requirements | AC380V 50Hz | AC380V 50Hz 3Kw | AC380V 50Hz |

| Total power | 3.5Kw | 3Kw | 5.5Kw |

| Applicable nuts | All types of nuts | Small-grain nuts | Small-package nuts |

What are the applications of Vertical Packaging Machine for Nuts?

Vertical Packaging Machine for Nuts can be widely used in the packaging of various nut products, including large nuts (such as walnuts, macadamia nuts, etc., which require special vibration feeding design), medium-sized nuts (cashews, almonds, etc.), small nuts (pistachios, melon seeds, etc.), as well as mixed nuts and processed nuts (roasted nuts, nut powder, etc.). It is also suitable for traditional roasted nuts packaging in the nut roasting industry, high-end snack packaging in the health food industry, quantitative packaging in the baking raw material industry, and can also be used for nut gift box packaging in the gift industry and export nut packaging that meets international standards, fully covering the packaging needs of different categories and industries.

![[field:title/]](/uploads/250613/1-250613153426319.jpg)