Chemical powder filling and sealing machine

A chemical powder filling and sealing machine is used for filling and sealing various types of chemical powders. It integrates screw metering, filling, and sealing operations to achieve quantitative filling and sealing of chemical powders such as pigments, dyes, and additives. This ensures a dust-free and moisture-proof packaging process, improving production efficiency and product quality.

The Chemical powder filling and sealing machine can package bags ranging from 5 grams to 50 kilograms, and can also be customized to meet specific needs. The filling and sealing speed is 20-80 bags per minute, depending on the model. Packaging bag materials include kraft paper, composite film, aluminum foil, and PE woven bags. Bag types include stand-up pouches, three-side seal bags, and four-side seal bags. Both horizontal and vertical models are available.

What types of chemical powder filling and sealing machines are available?

Depending on the properties of the chemical powder and space limitations at the packaging site, chemical powder filling and sealing machines are available in both vertical and horizontal types.

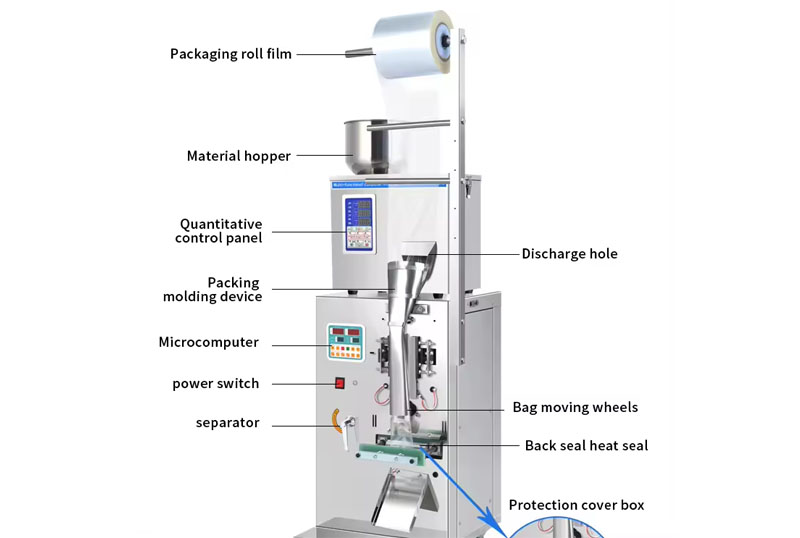

Vertical Chemical Powder Filling and Sealing Machine: This machine uses a top-down filling method, occupies less space, and has the material hopper located at the top. The packaging bags/containers open upwards. Commonly used for pre-made bags or stand-up pouches, it is suitable for compact workshops and is generally used for packaging small bags of chemical powder (5-5 kg). Packaging speed is 40-80 bags per minute. Vertical models have a faster packaging speed and are suitable for packaging chemical powders with good flowability.

Horizontal Chemical Powder Filling and Sealing Machine: This machine uses a horizontally advancing filling method, is longer, and occupies a larger horizontal area. The material hopper and filling head are located on the side, and the packaging bags are placed horizontally with the opening facing the side. Commonly used for pre-made bags or stand-up pouches, it can be used to package chemical powders of 100g-50kg per bag, packaging 20-50 bags per minute. Horizontal models have a slower packaging speed but are suitable for packaging chemical powders with poor flowability and static electricity.

What are the advantages of a chemical powder filling and sealing machine?

The chemical powder filling and sealing machine uses a screw metering device, which can control the filling error to ≤±0.5%. This ensures consistency in the packaging quantity of each bag and reduces the waste of raw materials and the problem of inaccurate metering caused by manual filling. The machine body is made of 304 stainless steel, which is smooth inside and out, leaves no powder residue, and is corrosion-resistant and rust-resistant. It can also handle special chemical powders such as acidic and alkaline powders. Equipped with a sealed dustproof structure, it effectively isolates powder dust and reduces environmental pollution. It can automatically complete filling, sealing, and labeling processes, packaging 20-80 bags of chemical powder per minute, which can be used for packaging needs from small-batch trial production to large-scale mass production. It also supports customization of different filling capacities, sealing methods, and metering devices.

What is the working principle of a chemical powder filling and sealing machine?

When a chemical powder filling and sealing machine is working, a screw conveyor first precisely and quantitatively delivers the chemical powder to the filling station. Under the control of the screw metering system, the chemical powder is accurately filled into packaging bags. The packaging bags then enter the sealing unit, where they are sealed using methods such as heat sealing, sewing, or screw capping, depending on the bag material, to ensure moisture and leakage prevention. The filling and sealing machine operates entirely in a closed or negative pressure environment, equipped with a dust removal device to prevent dust escape, ensuring production safety and cleanliness.

Chemical powder filling and sealing machine models

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of a chemical powder filling and sealing machine?

A chemical powder filling and sealing machine is used for the automated packaging of various dry, uniformly fine chemical powders. It can be used for packaging easily dusty and moisture-sensitive chemical powders such as coating powders, plastic powders, catalysts, flame retardants, protein powders, starch, and pharmaceutical intermediates. The filling and sealing machine can complete the entire process from metering and filling to bag making, sealing, and coding, and can handle various packaging forms such as bags, cans, and bottles. The filling and sealing machine can be used in conjunction with equipment such as screw feeders, crushers, screening machines, metal detectors, inkjet printers, box packers, and palletizers to achieve continuous and intelligent production from raw material processing to finished product stacking.

Chemical Powder Filling and Sealing Machine Customer Case

A fine chemical company in China successfully solved challenges related to dust loss, precision control, and human contact safety risks during the filling process of highly active catalyst powders by adopting a chemical powder filling and sealing machine. The machine is used in an oxygen-free, cleanroom to package fine-particle, easily floating precious metal catalyst powders. The packaging weight per bag is precisely controlled at 500g, with a packaging speed of up to 25 bags per minute. The machine uses stand-up zipper bags made of aluminum foil composite material, with bag dimensions of 200mm*150mm. Through a series of streamlined operations including automatic bag loading, vacuum deoxygenation, precise filling, and heat sealing, the machine not only achieves high sealing performance and extends product shelf life but also improves production safety and efficiency.

Chemical Powder Filling and Sealing Machine Manufacturer

Dahan Chemical Powder Filling and Sealing Machine Manufacturer mainly produces vertical and horizontal chemical powder filling and sealing machines, as well as other filling and sealing machines. These are available in fully automatic and semi-automatic models, with a complete range of specifications. Metering devices include screw type and weighing type. We can also customize packaging bag materials, sizes, and capacities according to the properties of the chemical powder.

Saturday December-20 2025 15:19:35