Vertical Form Fill Seal Machine For Powder

The Vertical Form Fill Seal Machine for Powder is a packaging machine that automates the entire process of powder material production, from raw material to finished bag, including bag making, filling, and sealing, using a screw metering system. This packaging method reduces labor costs, improves packaging efficiency, and provides precise measurement of each bag's weight, with an error controlled within ±1g, ensuring consistency across all bags. It can package 30-150 bags of powder per minute and supports three-side seal, four-side seal, back seal, and pillow-type bag types. Typical dimensions are 30-200mm wide and 50-300mm high, but customization is also available.

The Vertical Form Fill Seal Machine for Powder can be used for packaging dry, free-flowing powders, granular powders, and lightweight powders such as flour, milk powder, spices, cocoa powder, traditional Chinese medicine powder, and feed powder. Each bag can be sized from 1-5000 grams. However, it cannot be used for packaging highly hygroscopic and easily caking soda powder, ultrafine easily airborne graphite powder, flammable and explosive gunpowder powder, or corrosive powder. These powder materials can easily cause machine blockage, inaccurate measurement, or safety risks.

What types of Vertical Form Fill Seal Machines for Powder are there?

The metering method used in Vertical Form Fill Seal Machines for Powder varies depending on the type of powder being packaged and the production volume requirements. There are three main types: screw type, measuring cup type, and weighing type.

Screw-type Vertical Form Fill Seal Machine for Powder: This machine measures and pushes powdered material by the number of screw rotations. It is used in conjunction with vertical bag making and heat-sealing processes to package powdered materials. Each bag can be sized from 1 gram to 5 kilograms, with a packaging speed of 40-80 bags per minute. It can be used for packaging fine powders, micro powders, and powders with moderate flowability, such as milk powder, traditional Chinese medicine powder, protein powder, flour, and coffee powder.

Measuring Cup-type Vertical Form Fill Seal Machine for Powder: This machine uses a measuring cup to quantitatively scoop powdered material, which is then filled into forming bags through the feeding port. Each bag can be sized from 5 grams to 500 grams, with a packaging speed of 30-150 bags per minute. This is the fastest packaging speed and is commonly used for packaging free-flowing, non-clumping powders such as sugar powder, monosodium glutamate powder, feed premix powder, and laundry detergent.

Weighing Vertical Form Fill Seal Machine for Powder: This machine uses an electronic scale to accurately weigh the material and then feeds it into a forming bag for sealing and packaging. It has the highest measurement accuracy, but the packaging speed is relatively slow, generally 10-40 bags/minute. It is often used for packaging high-value powders and powders that require precise measurement, such as health product powders, Western medicine powders, precious metal powders, and chemical raw material powders.

What are the advantages of a Vertical Form Fill Seal Machine for Powder?

How does the Vertical Form Fill Seal Machine for Powder work?

When the Vertical Form Fill Seal Machine for Powder is in operation, the roll film is stretched vertically and folded into the desired bag shape. The formed packaging bag moves downward to the filling position, and the powder is fed into the opened packaging bag through a metering device. The bag filled with powder moves downward to the sealing position for heat sealing, and at the same time, the connected packaging bags are cut. The finished product is then conveyed to the next process for further processing.

Vertical Form Fill Seal Machine For Powder Parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the structures of the Vertical Form Fill Seal Machine For Powder?

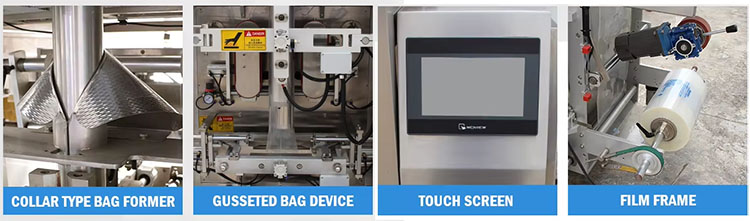

The Vertical Form Fill Seal Machine for Powder mainly consists of a film conveying system composed of a film roll support, tension controller, and guide rollers; a bag-making unit composed of a neck forming machine, a longitudinal sealing machine, and a film folding mechanism; a powder filling system composed of a hopper and metering device; a sealing system for sealing; and a control system for setting parameters such as bag length, filling weight, and speed.

What are the applications of the Vertical Form Fill Seal Machine for Powder?

The Vertical Form Fill Seal Machine for Powder can be used in the food, pharmaceutical, chemical, daily chemical, and agricultural industries for packaging various dry, free-flowing powder materials, including milk powder, coffee powder, soy milk powder, protein powder, flour, starch, seasoning powders (such as pepper powder and five-spice powder), instant beverage powder, traditional Chinese medicine powder, Western medicine powder, health product powder, probiotic powder, vitamin powder, laundry detergent, detergent powder, paint powder, dye powder, plastic granule powder, pesticide powder, feed additive powder, and fertilizer powder.

Vertical Form Fill Seal Machine for Powder Customer Cases

| Application Industries | Typical Materials | Material Characteristics | Packaging Specifications | Sealing Requirements | Equipment Compatibility Considerations |

| Food Industry | Milk Powder, Coffee Powder, Seasoning Powder | Easily absorbs moisture, uneven flowability | 5g-1kg/bag | Sealed and moisture-proof, odorless and pollution-free | Food-grade contact material, precise measurement, error ±1%, prevents dust spillage |

| Pharmaceutical Industry | Traditional Chinese Medicine Powder, Probiotic Powder, Western Medicine Powder | High aseptic requirements, easily oxidized | 1g-500g/bag | Aseptic sealing, prevents secondary contamination | Complies with GMP standards, can be equipped with UV sterilization, sealing strength ±30N/15mm |

| Chemical Industry | Laundry Detergent, Paint Powder, Dye Powder | Corrosive/Irritating, Easily Creates Dust | 100g-5kg/bag | Leak-proof, Acid and Alkali Resistant | 304 Stainless Steel Corrosion-resistant Material, Large Diameter Feed Inlet, Strong Sealing |

| Agricultural Industry | Pesticide Powder, Fertilizer Powder, Feed Additive Powder | High Density, Irritating | 500g-10kg/bag | Anti-Volatile, Moisture-proof and Explosion-proof | Thickened Bag Body for Fit, Wide Quantity Range, Anti-static Design |

Manufacturer of Vertical Form Fill Seal Machines for Powders

Dahan manufactures fully automatic or semi-automatic vertical form fill seal machines for powders, including multi-row back-sealing machines, which can be paired with spiral/belt/bucket feeders. Packaging bag types include three-side seal, four-side seal, back seal, stand-up pouches, zipper bags, eight-side seal, and spout bags. Packaging materials include PET/AL/PE composite film, kraft paper, aluminum foil bags, PE film, and woven bags. Food-grade/pharmaceutical-grade materials (such as 316L stainless steel contact materials) are available depending on the material being packaged. Customization services include metering range adjustment, sealing methods (heat sealing/ultrasonic sealing), and additional functions depending on the material type, such as sterilization, dust extraction, static electricity removal, and nitrogen filling for preservation.

Saturday November-08 2025 16:09:07