What is vertical packaging machine for coffee beans?

Vertical packaging machine for coffee beans is a device used to achieve efficient conversion of coffee beans from bulk to exquisite finished product packaging. Coffee bean packaging directly affects product quality preservation, transportation convenience and shelf appeal. Our equipment adopts a vertical bag making-filling-sealing integrated design, which perfectly solves various challenges in packaging, such as uneven coffee bean particle size, easy oxidation, and moisture-proof characteristics. It is particularly suitable for automated packaging of roasted coffee beans, and can effectively maintain the freshness and flavor characteristics of coffee beans.

What types of vertical packaging machines are there for coffee beans?

Vertical packaging machines for coffee beans can be divided into three types: particle metering type, nitrogen filling and preservation type, and multifunctional combination type. You can choose according to the needs of packaging coffee beans:

Particle metering vertical packaging machine for coffee beans: For coffee beans of different particle sizes, the weight of each bag of coffee beans is ensured to be consistent through precise metering devices. Whether it is small-particle boutique coffee beans or large-particle blended beans, stable and high-precision packaging can be achieved, which is suitable for retail packaging scenarios and meets consumers' needs for quantitative packaging.

Nitrogen filling and preservation vertical packaging machine for coffee beans: In view of the fact that coffee beans are easily oxidized and affect the flavor, the equipment first extracts the air in the package and then fills it with inert gases such as nitrogen during the packaging process to create a low-oxygen environment, extend the shelf life of coffee beans, and retain the aroma and flavor of coffee to the greatest extent. It is especially suitable for boutique coffee brands with extremely high quality requirements.

Multifunctional combination vertical packaging machine for coffee beans: It integrates multiple functions such as metering, nitrogen filling, sealing, and labeling, and can complete the complex coffee bean packaging process in one stop. It can not only realize basic packaging operations, but also meet personalized packaging needs, such as accurately affixing brand logos, product information, etc. on the packaging. It is suitable for coffee companies that engage in large-scale production and focus on brand image display.

Why choose a vertical packaging machine to package coffee beans?

Compared with traditional packaging methods, vertical packaging machine for coffee beans has unique advantages:

High space efficiency: The vertical design occupies a small area and is suitable for coffee roasting workshops with limited space.

Adapt to the characteristics of coffee beans: The specially designed feeding system avoids coffee bean breakage and keeps the whole grains.

Excellent preservation performance: It can integrate a variety of preservation technologies to solve the problems of oxidation and aroma loss of coffee beans after packaging.

Beautiful and uniform packaging: Automated control ensures that each packaging bag is neatly sealed and the date code is clear, which improves the product grade.

| Comparison items | Vertical coffee bean packaging machine | Ordinary packaging machine |

| Packaging method | Automatic bag making, filling, and sealing integration | Pre-made bags are required, and manual intervention is more |

| Freshness preservation ability | Supports nitrogen replacement to extend the freshness of coffee beans | No gas replacement function is usually available |

| Packaging speed | 30-150 bags/minute (adjustable) | 10-30 bags/minute |

| Bag type selection | Pillow bag, gusset bag, stand-up bag, four-side seal | Simple bag type only |

| Applicable materials | Whole beans and ground coffee powder are both available | Usually limited to a single form |

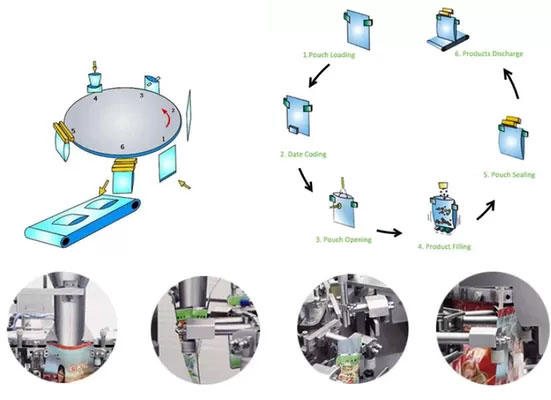

How does the vertical packaging machine for coffee beans work?

When the vertical packaging machine for coffee beans works: coffee beans enter the metering device from the hopper and are accurately metered by a screw or a measuring cup; at the same time, the packaging film is unwound from the unwinding device and wrapped into a cylinder by the former; the measured coffee beans fall into the packaging film cylinder, and then the longitudinal and transverse sealing operations are performed to seal the coffee beans in the packaging bag; finally, the cutting device cuts the packaged coffee bean bag according to the set length to complete the entire packaging process. In the nitrogen-filled model, vacuuming and nitrogen filling operations are also performed before sealing to ensure a low-oxygen environment in the package.

Vertical Packaging Machine for Coffee Beans Parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of vertical packaging machine for coffee beans?

Vertical packaging machine for coffee beans is widely used in coffee roasting workshops, commercial coffee production, specialty coffee packaging, coffee gift sets, coffee chain brands and other coffee-related scenarios to meet the packaging needs of small batches and multiple varieties of boutique coffee, and flexibly switch the packaging of coffee beans with different roasting degrees.

Vertical packaging machine for coffee beans customer case

Automation upgrade for boutique coffee roasters: The customer originally used manual packaging, with a daily production capacity of only 500 bags. After configuring our basic vertical packaging machine, the production capacity increased to 2,000 bags/day, with a packaging accuracy of ±1g, perfectly presenting the quality of boutique coffee.

Nitrogen fresh-keeping packaging for exported coffee beans: Customized atmosphere-controlled vertical packaging machines for customers exporting to the Middle East, integrated nitrogen flushing and residual oxygen detection, oxygen content in the package <1%, and shelf life extended by 3 times.