Vertical packaging machine for candy granules

Vertical packaging machines for candy granules automatically package bulk candy granules into bags. They automatically complete a series of operations including feeding, metering, bag making, filling, and sealing, replacing manual labor, improving packaging efficiency, and extending the shelf life of the candy. Each bag contains between 5 and 500 grams, with a packaging speed typically between 40 and 150 bags per minute. Depending on the properties of the candy granules, the packaging bag materials include food-grade composite films such as PET/PE and OPP/CPP, as well as aluminized films. Packaging types include back-seal bags, three-side-seal bags, four-side-seal bags, and stand-up zipper bags. Bag sizes can be customized according to the size of the candy granules and the packaging scenario, generally with a width of 10-200 mm and a length of 20-300 mm.

What types of vertical packaging machines for candy granules are available?

There are two main types of vertical packaging machines for candy granules: screw-type and weighing-type. These two types differ in their metering methods, packaging speed, packaging volume, and bag size.

Screw-type vertical packaging machines for candy granules: These machines use a screw conveyor to measure the candy granules. They offer fast conveying speeds, a simple structure, and lower costs. They are suitable for packaging small or free-flowing candy granules, such as hard candies, mints, bean candies, soft candies, and milk candy fragments. Packaging speeds are 40-150 bags/minute, with each bag containing 5-50 grams. Bag dimensions are 10-150mm wide and 20-250mm long.

High-precision sensors and multiple vibrating hoppers are used for combined weighing. Vertical packaging machine for candy granules: This machine uses a combination of weighing sensors and vibrating hoppers for weighing, providing high measurement accuracy. It can be used to package candies with uneven particle size, irregular shape, easy sticking, or large particles, such as pralines, nougat granules, soft candies, chocolate chips, filled candies, liqueur-filled candies, and soft candies with fruit pieces. Packaging speed is 30-100 bags/minute, packaging quantity is 10-100 grams/bag, and bag size is 15-200mm wide and 30-300mm long, with adjustable dimensions.

What are the advantages of a vertical packaging machine for candy granules?

The vertical design of the vertical packaging machine for candy granules saves space. The entire machine is made of 304 stainless steel with internal and external polishing, making it resistant to acid and alkali corrosion, easy to clean, and rust-free, meeting food hygiene standards. It uses a high-precision metering method, which can be flexibly adjusted according to the size and weight of the candy granules, avoiding waste and ensuring consistency in the specifications of each bag. It offers various packaging formats, including pillow-type, backpack-type, and three-side-seal bags, and the bag size can be customized according to requirements. The fully automatic packaging machine can package 300-1500 bags per hour, which is more than 90% faster than manual packaging.

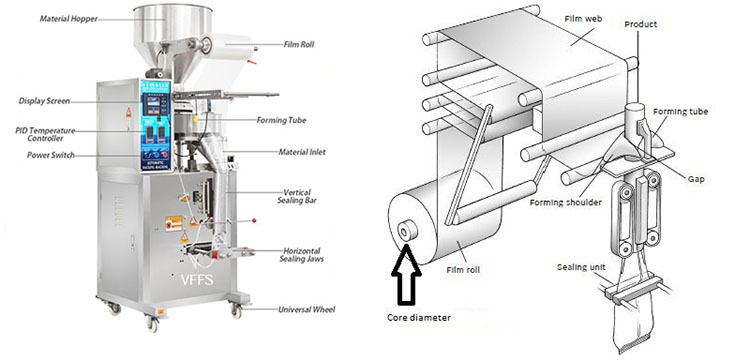

How does a vertical packaging machine for candy granules work?

When a vertical packaging machine for candy granules is working, a vibrating feeder transports candy granules to a metering device, where they are weighed according to a preset weight or quantity. The weighed granules then fall into a forming film cylinder, where a horizontal sealing mechanism heat-seals both ends and simultaneously cuts them into individual packaging bags. Finally, the finished bags are output via a conveyor belt. The entire process—feeding, metering, bag making, filling, sealing, and bag cutting—is fully automated.

Specifications of a vertical packaging machine for candy granules

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the materials and types of packaging bags used in vertical packaging machines for candy granules?

Packaging bags for vertical packaging machines for candy granules are generally made of composite films to meet the packaging needs of different types of candy. PET/PE composite films are stiff and moisture-proof, with a high gloss surface that allows the candy's appearance to be clearly seen. They can be used for packaging ordinary hard candies, fruit candies, and other candy granules that do not require special light protection. OPP/CPP composite films have good transparency, strong heat-sealing properties, and a softer texture. They can be used for packaging soft candies, milk candies, and other candy granules that are prone to sticking together, reducing material adhesion during packaging. Aluminum-plastic composite films have good light-blocking and oxygen-barrier properties, extending the shelf life of candies. They are suitable for packaging light-sensitive and easily oxidized candy granules such as chocolate chips and filled candies.

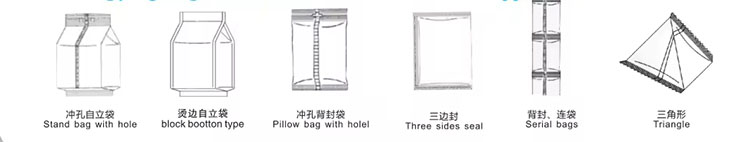

Regarding the choice of packaging bag type for vertical packaging machines for candy granules, different bag types are suitable for different types of candy granules and packaging scenarios. Back-seal bags offer excellent sealing and a flat shape, making them suitable for packaging multiple hard candies and brittle candies, facilitating bulk packing later. Three-side seal bags provide a strong seal and are compact, ideal for single or small-quantity candy granules such as wedding candies and bulk weighed candies. Stand-up pouches with a bottom support structure allow for upright placement, facilitating shelf display, and are suitable for large packages of candy granules, such as family-sized fruit hard candies and children's candies.

What are the applications of vertical packaging machines for candy granules?

Vertical packaging machines for candy granules can be used for packaging candy granules in the food processing stage. They can meet the packaging needs of small to large candy production plants, and can also be used for small-batch customized packaging in snack shops, supermarkets, and other similar settings. They can package various types of candy granules, including hard candy granules such as fruit candies and mints, soft candy granules such as QQ candies and gummy candies, and milk candy granules (such as plain milk candies and filled milk candies). They can also package coated candy granules (such as chocolate-coated candy granules). Furthermore, they can package small or irregularly shaped candy snacks, such as cookies, puffed snacks, roasted nuts and dried fruits, and chocolate beans.

Vertical packaging machine for candy granules manufacturer

DaHan Vertical Packaging Machine for Candy Granules manufactures a variety of packaging equipment, including multi-head scale vertical packaging machines, small packaging machines, high-speed vertical packaging machines, and irregularly shaped vertical packaging machines. A complete range of models and specifications are available to meet the packaging needs of various candy granules, such as hard candy, soft candy, and granulated candy, from 5g to 5kg. Materials include rust-resistant and food-grade SUS304 stainless steel and powder-coated carbon steel, but stainless steel is the preferred choice for food contact parts. Prices range from $450 to $12,000 USD; direct from the manufacturer, prices are negotiable. In addition to standard models, customized services are available, such as bag type (pillow bags, perforated hanging bags, etc.), metering devices (multi-head scales, measuring cups, etc.), and the addition of conveyors or nitrogen generators, to meet different production capacity and packaging needs.

Friday October-31 2025 18:01:47