What is vertical packaging machine for sugar?

Vertical packaging machine for sugar is an automated packaging equipment designed for the candy industry. It adopts vertical bag making-filling-sealing integrated technology and is suitable for quantitative packaging of hard candy, soft candy, QQ candy, chocolate, milk candy and other candies. In the candy production process, the packaging link directly affects the product quality, shelf appeal and production efficiency. The vertical packaging machine has the advantages of high efficiency, high precision and low loss, which can greatly increase the packaging speed of the production line and ensure the freshness and sealing of the candy.

Compared with traditional manual packaging or semi-automatic equipment, vertical packaging machine for sugar can greatly reduce labor costs, improve packaging consistency, and adapt to a variety of packaging forms such as pillow bags, back-sealed bags, and gusseted bags to meet the needs of different candy products.

What types of vertical packaging machines for sugar are there?

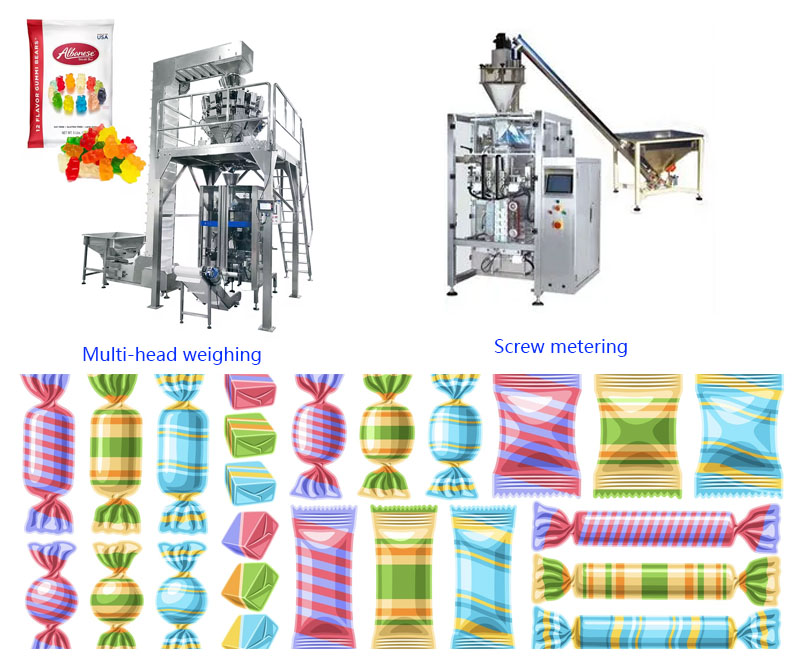

According to different types of candies, vertical packaging machine for sugar can be classified into multi-head weighing and screw metering types according to the metering method; according to the packaging bag type, they can be divided into pillow bags, self-supporting bags, back-seal/three-side-seal bags. You can choose the appropriate model according to the characteristics of the packaged candies.

| Classification of measurement methods | Multi-head weighing | Applicable to hard candies, chocolates, etc. with high precision requirements, with an error of ±1 gram |

| Screw metering | Applicable to powdered candies (such as mixed packaging of powdered sugar and milk powder) | |

| Bag type classification | Pillow bag | Common in hard candy and lollipop packaging |

| Stand-up bag | Applicable to liquid candy (such as jelly, syrup) | |

| Back seal/three-side seal bag | Widely used in milk candy and chocolate granule packaging |

What are the advantages of vertical packaging machine for sugar?

Vertical packaging machine for sugar adopts fully automated packaging: from film roll bag making, metering and filling to sealing and coding, no manual intervention is required throughout the process, high speed and high efficiency.

High speed and high efficiency: the candy packaging speed can reach 20-250 bags/minute, fully automatic packaging, more than 10 times faster than manual packaging.

Accurate measurement: servo motor + PLC control is adopted to ensure that the weight error of each bag of candy is ≤±1%3.

Diversified bag types: support pillow bags, back-sealed bags, gusset bags, self-supporting bags, etc., to enhance the diversified display effect of candy packaging.

Food grade material: the parts in contact with candy are made of food grade stainless steel or materials that meet food hygiene standards to ensure the safety and hygiene of the packaging process.

How does the vertical packaging machine for sugar work?

When the vertical packaging machine for sugar is working, the packaging film is unwound from the film rolling device, and the guide rollers and tension control system ensure that the film is flat and stably transported to the former. At the former, the film is rolled into a tube around the forming mold, and the film is longitudinally sealed by heat sealing or ultrasonic sealing technology to form a packaging tube; at the same time, the candy falls accurately into the packaging tube from the hopper through the feeding device. The feeding device can use different methods such as vibration feeding and screw feeding according to the characteristics of the candy and packaging requirements to ensure that the candy enters the packaging tube accurately and smoothly. When the candy in the packaging tube reaches the predetermined number or weight, the horizontal sealing device starts to seal the packaging tube horizontally and cut off the packaging to form an independent packaging unit. The whole process is precisely controlled by a programmable logic controller (PLC), and all components work together to achieve efficient and accurate packaging.

Vertical packaging machine for sugar technical parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of vertical packaging machine for sugar?

Vertical packaging machine for sugar can be used for various powders, granules, liquids, and irregular sugars, such as: high-speed pillow bag packaging for hard candy/lollipops, automatic punching and hanging bags; measuring cup measurement for soft candy/QQ candy to ensure that the granules are intact and non-sticky; modified atmosphere packaging (nitrogen filling for freshness) for chocolate/milk candy to extend the shelf life; multiple varieties of combined weighing can be selected for mixed candy gift boxes to improve packaging flexibility, etc.

How to choose a vertical packaging machine for sugar?

When choosing a vertical packaging machine for sugar, you need to consider the type of candy, packaging speed, packaging bag style, packaging size, etc., as follows:

Determine the characteristics of the sugar: particle size, viscosity, whether it needs moisture protection/nitrogen filling?

Choose packaging speed: small-scale production (20-60 bags/minute) vs. large-scale (100+ bags/minute).

Customized bag type: pillow bag (standard retail), self-supporting bag (high-end gift).

Additional functions: Do you need to punch holes, label, or fill with nitrogen for freshness preservation?

![[field:title/]](/uploads/250605/1-250605153I4G6.jpg)