Vertical Packaging Machine for Chili Powder

Vertical Packaging Machine for Chili Powder is a fully automatic packaging machine designed for high-dust, easily oxidizable powder materials such as chili powder. It achieves efficient and hygienic continuous packaging through a vertical bag-making-metering-filling-sealing integrated process. The machine is made of food-grade 304 stainless steel, with a fully enclosed airtight chassis and a negative pressure dust removal system, which can effectively control dust flying. It also supports flexible packaging from small bags (5g) to large bags (500g), meeting the diverse needs of seasoning production, restaurant chains and other scenarios.

What types of Vertical Packaging Machine for Chili Powder are there?

Vertical Packaging Machine for Chili Powder can be classified according to packaging form, metering method, functional configuration, etc., and can be selected according to the characteristics of chili powder and packaging requirements

| By packaging form | Three-side sealing | Suitable for small-sized retail packaging (such as 5-50g), with strong sealing, moisture-proof and oxidation-proof. |

| Four-side sealing type | The packaging has a strong three-dimensional sense, suitable for differentiated packaging of high-end chili powder brands | |

| Measuring method | Screw metering type | Accuracy ±1%, suitable for conventional chili powder (particles ≤0.5mm). |

| Weighing metering type | Accuracy ±0.5%, suitable for chili powder with poor fluidity or particles. | |

| Functional configuration | Basic type | Standard bag making + metering function, economical and practical. |

| Intelligent | Integrated nitrogen filling and preservation, automatic detection and rejection, remote monitoring and other functions to extend the shelf life of chili powder. |

What are the advantages of vertical packaging machine for chili powder?

Maintain freshness: The vertical packaging machine for chili powder uses sealed packaging bags for packaging, which can effectively prevent chili powder from contacting with external air, moisture, light and odor.

Prevent pollution: It can avoid the problems of unclean or unsanitary manual operations that may exist in manual packaging, and ensure the sanitary quality of chili powder.

Convenient storage and transportation: The vertical packaging machine for chili powder packs chili powder into sealed packaging bags, making it easier to store and transport, reducing loss and waste, and convenient for stacking and handling.

Accurate measurement and consistency: The vertical packaging machine for chili powder is equipped with a precise metering device, which can accurately measure the amount of chili powder in each packaging bag to ensure the consistency of the product.

Maintain freshness: The packaging machine can effectively seal the packaging bag to prevent the chili powder from moisture and oxidation, extend the shelf life of the chili powder, and maintain the freshness and taste of the product.

Moisture and insect prevention: Through effective packaging sealing performance, the packaging machine can prevent moisture and insect pests from invading, protecting the quality and sanitary safety of chili powder.

What are the applications of Vertical Packaging Machine for Chili Powder?

Pure chili powder: The chili powder vertical packaging machine is widely used to package pure chili powder. It can automatically fill and seal pure chili powder according to the preset packaging capacity and speed, improving production efficiency.

Chili powder: Chili powder is a chili product made by chopping and grinding chili peppers into granules, which is often used to increase the spiciness in cooking. The packaging machine can be used to package chili powder to keep its granular shape and prevent moisture and insects.

Chili granules: Chili granules are chili products made by cutting chili peppers into small granules, which are often used in seasoning and cooking. The packaging machine can accurately package chili granules to maintain their shape and quality.

Seasoning mixtures: In addition to pure chili powder, the chili powder vertical packaging machine is also suitable for packaging chili mixed seasonings. These seasoning mixtures may contain a variety of ingredients such as chili powder, salt, spices, vegetable powder, etc., which are used to make chili seasonings or seasoning formulas.

Seasoning bags/bag seasonings: The chili powder vertical packaging machine can also be used to package chili powder seasoning bags or bag seasonings. These seasoning bags are usually individually packaged small bags, which are convenient for consumers to add the right amount of chili powder during cooking.

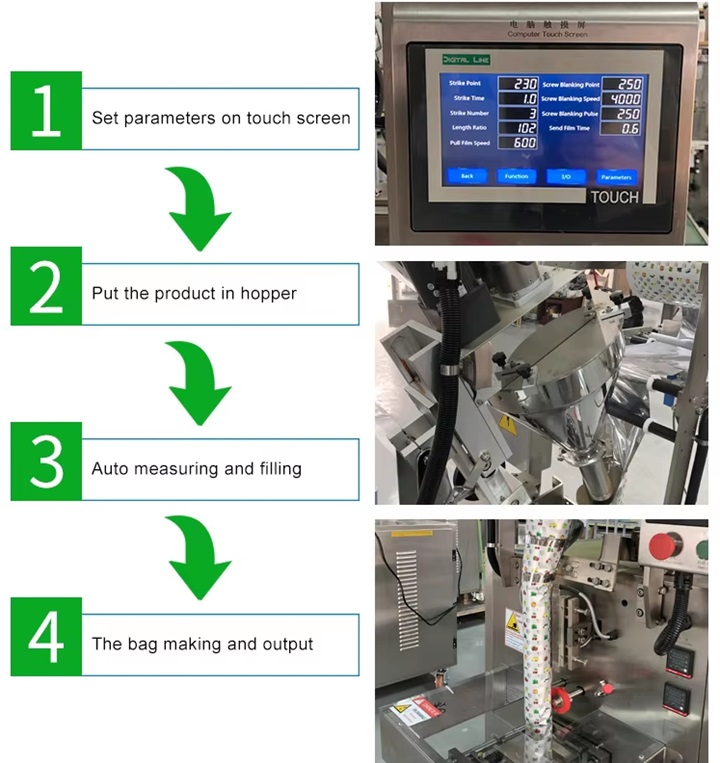

How does Vertical Packaging Machine for Chili Powder work?

The vertical packaging machine for chili powder is an automated packaging equipment. Its working principle is as follows: First, the pre-prepared chili powder is loaded into the hopper of the packaging machine. Through the set parameters, the packaging machine will automatically perform the following steps: The chili powder is conveyed to the metering device and accurately measured according to the set packaging weight. Next, the powder is evenly distributed in the forming mold through the vibrator to form the bottom of the bag. Then, the heat sealing device seals the bag mouth. At the same time, the packaging machine can also perform coding, counting, batch number printing and other functions as needed. Finally, the finished bag is discharged through the conveyor belt to complete the packaging process. The whole process realizes automated operation, improves packaging efficiency, and ensures the accuracy and consistency of packaging. This working principle makes the vertical packaging machine for chili powder widely used in the chili industry, bringing efficiency improvement and cost savings to production companies.

Chilli Powder Filling Machine Parameter

| Packaging weight range | Conveying spee | Packing speed | Measuring accura | Sealing form |

| 5g-20g | 30-60 bags/minute | 20-40 bags per minute | ±0.2g | Heat seal |

| 20g-50g | 20-40 bags/minute | 15-30 bags per minute | ±0.5g | Heat seal |

| 50g-100g | 15-30 bags/minute | 10-20 bags per minute | ±1g | Heat seal |

| 100g or more | 10-20 bags/minute | 5-15 bags per minute | ±2g | Heat seal |

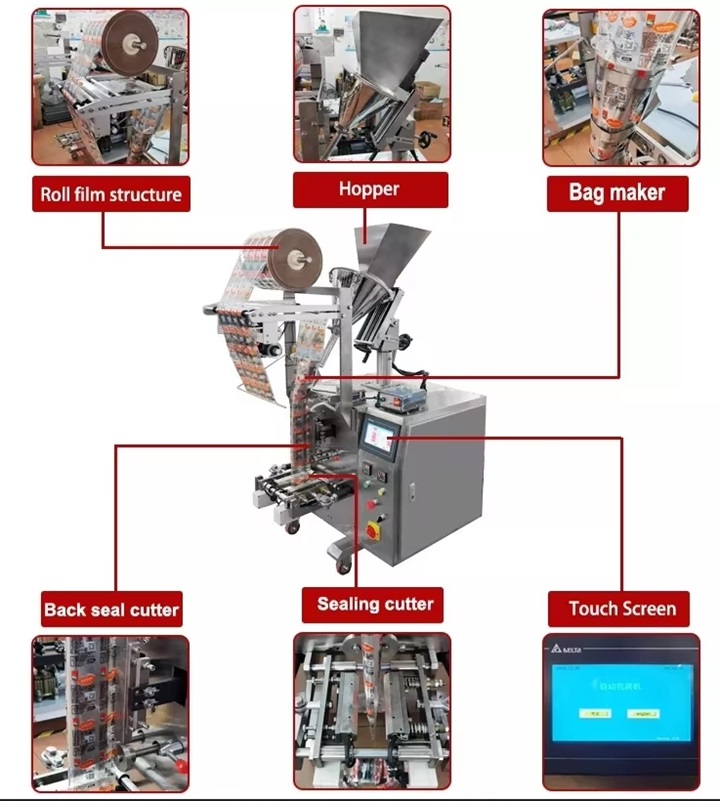

Chili powder vertical packaging machine structure

The chili powder vertical packaging machine consists of a conveying system, a metering system, a packaging system and a control system. The conveying system transports the chili powder to the packaging machine, the metering system accurately measures, the packaging system bags and seals, and the control system monitors the operation. These components work closely together to ensure that the chili powder is accurately packaged, maintains freshness, improves efficiency, adapts to different specifications, reduces error rates, and saves costs. It is an important tool for manufacturers to improve packaging efficiency and quality.

Vertical Packaging Machine for Chili Powder Customer Case

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A large condiment manufacturer in India mainly produces powdered condiments such as chili powder and spice powder, which need to meet food-grade packaging requirements to ensure moisture-proof, leak-proof and long shelf life. | 50g-500g | 90 bags/minute | Bag size range (L) 50-200mm × (W) 50-150mm, customized corner bags, linked bags, etc. | Polyester/aluminum-plated/polyethylene composite film, with good moisture resistance and heat sealing properties |

| A regional chili powder processing plant in North America, whose products are mainly supplied to the local catering market and retail channels, needs to take into account both cost and packaging efficiency. | 20g-100g small package | 120 bags/minute | Bag size 60-80mm (length) × 70-120mm (width), supports three-side sealing and four-side sealing bag types | Polyethylene nylon composite film, with anti-leakage and good heat sealing performance |

| A high-end chili powder brand, the product is mainly in the boutique market, requires high-precision measurement and beautiful packaging, and supports nitrogen filling for freshness preservation. | 100g-1kg | 60 bags/minute | Customized 200mm (length) × 150mm (width) vertical bag | Multi-layer aluminum foil composite film, with high barrier properties, extending product shelf life |

How to choose Vertical Packaging Machine for Chili Powder?

Material characteristics: particle size (0.1-0.5mm, choose screw metering; 0.5-2mm needs to be weighed); humidity (water content>8% needs to be equipped with moisture-proof sealing type)

Production requirements: daily output <1 ton (select LBP-200 type, occupying 2㎡); daily output >5 tons (select LBP-500 type, supporting multi-row packaging).

Environmental requirements: explosion-proof motor + anti-static coating is required for explosion-proof areas.

Budget and function: basic requirements (give priority to screw metering type, cost reduction of 20%), high-end requirements (intelligent nitrogen filling + detection, premium space increased by 30%).

Chili powder vertical packaging machine price

The price of chili powder vertical packaging machine varies according to many factors, including the machine's specifications, functions, brand, quality and market supply and demand. Generally speaking, the price of small and medium-sized chili powder vertical packaging machines ranges from US$1,000 to US$5,000, while large and high-performance packaging machines may cost more than US$10,000. The specific price also depends on factors such as the production materials, technological innovation, degree of automation and production capacity of the packaging machine. In addition, the price may increase for specific customized needs and additional functions. When purchasing, it is recommended to choose a chili powder vertical packaging machine that suits you based on actual needs, taking into account factors such as price, quality, after-sales service and supplier reputation.

Wednesday September-03 2025 18:02:00