VFFS machine for milk powder packaging

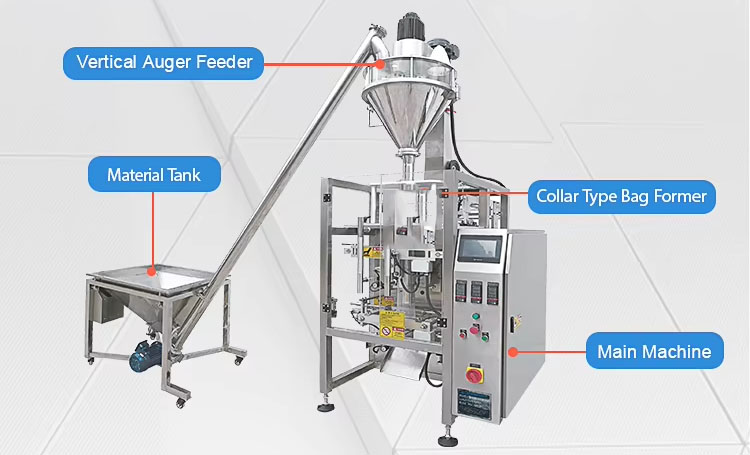

The VFFS machine for milk powder packaging automates the entire process of milk powder production, from bag making and metering to filling, sealing, and outputting the finished product. It packages bulk milk powder into 10g-1000g bags, replacing manual labor in the entire process. The packaging speed is 30-120 bags per minute.

The VFFS machine for milk powder packaging offers various bag types, including three-side seal, four-side seal, and back seal bags. Bag dimensions can be adjusted to meet specific needs, typically with a width of 50-200 mm and a length of 80-300 mm. The bags are usually made of composite films such as PET/PE or aluminum-plastic composite film, which effectively blocks light, oxygen, and moisture, extending the shelf life of the milk powder.

What types of VFFS machines are available for milk powder packaging?

VFFS machines for milk powder packaging can be categorized into three types based on the milk powder metering and filling method: measuring cup type, screw type, and weighing type. These different types differ in terms of output and metering accuracy.

Measuring cup type VFFS machine for milk powder packaging: These use a fixed-volume measuring cup to scoop milk powder. Available volumes include 50ml, 100ml, 150ml, 200ml, 300ml, and 500ml. They are commonly used for small to medium-sized packaging (5g-500g/bag). They can process 30-80 bags per minute and ensure good flowability and relatively uniform powder consistency. They are not suitable for packaging lumpy milk powder as they can easily lead to metering errors.

Screw-type VFFS machine for milk powder packaging: This machine uses a rotating screw to push milk powder, ensuring precise measurement, minimizing dust generation, and preventing powder waste. Single-bag packaging ranges from 10g small packages to 1kg large packages. Its packaging speed is faster than the measuring cup type, reaching 60-120 bags per minute. It is suitable for packaging free-flowing, easily clumped, whey protein-containing specialty formula milk powders, and modified milk powders containing a small amount of particles. Its application range is wide.

Weighing-type VFFS machine for milk powder packaging: This machine accurately weighs the milk powder before filling it into bags. It offers the highest measurement accuracy of the three types. Single-bag packaging ranges from 5g trial packs to 5kg family packs. It is often used for high-end milk powder packaging such as infant formula milk powder where high precision is required. However, its packaging speed is slower, at 20-60 bags per minute.

What are the advantages of the VFFS machine for milk powder packaging?

The VFFS machine for milk powder packaging is made entirely of stainless steel, with a smooth, clean, and hygienic surface, ensuring no packaging residue and preventing material contamination. It can fully automate the entire packaging process for milk powder, from bag making to sealing, reducing manual intervention and ensuring both milk powder quality and packaging efficiency. Equipped with three measuring methods—measuring cup, screw, and weighing—there's bound to be one that meets your milk powder packaging needs. The precise measurement avoids the measurement errors inherent in manual packaging. Single bag packaging quantities range from 5g to 5000g, with various specifications available. Packaging speed is fast, up to 120 bags per minute, and it also supports different bag shapes such as three-side seal, four-side seal, and back seal.

How does a VFFS machine for milk powder packaging work?

When a VFFS machine for milk powder packaging is working, the packaging film is first stretched into the required bag shape. Milk powder falls from the hopper into the screw conveyor channel and is fed into the bag by the screw. The screw conveyor prevents clumping and precisely controls the packaging quantity of each bag. The filled milk powder bags are then heat-sealed. The connected milk powder bags are then cut, and the finished bags fall below to the finished product area.

VFFS machine for milk powder packaging parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of a VFFS machine for milk powder packaging?

The VFFS machine for milk powder packaging can package different types of bulk milk powder into finished bags. It can be used in the food, baby product, and dairy processing industries to package infant formula, toddler formula, adult whole/skim milk powder, high-calcium low-fat milk powder for middle-aged and elderly people, milk powder for pregnant women, goat milk powder, organic milk powder, probiotic milk powder, and other milk powders with varying flowability and particle sizes. It can quickly complete the entire process from roll forming, precise filling, sealing, to batch number printing. It supports various packaging sizes, including small bags (5-50g), medium bags (100-500g), and large bags (1000g-5000g), meeting the needs of retail, family packs, and baby stores.

VFFS machine for milk powder packaging customer case

A Chinese infant formula manufacturer needed to address its small-batch, multi-specification automated packaging requirements. They selected the VFFS machine for milk powder packaging to build a production line for packaging free-flowing powders such as whole milk powder, skim milk powder, and infant formula. The requirements included flexible packaging sizes from 10g to 100g per bag, catering to various sales scenarios such as trial packs and portable packs. Packaging speeds reached 30-60 bags per minute, requiring common bag types such as stand-up pouches and back-seal bags. Materials compatible with moisture-proof and sealing materials such as PET/AL/PE composite film and aluminized film were essential. Bag sizes could be customized from 80×120mm to 150×220mm. The equipment uses a precision filling system to control metering errors to ≤±1%, and a heat-sealing process to ensure a tight seal and prevent powder leakage. The finished bags have a smooth appearance and clear printing, effectively isolating air and moisture, extending the shelf life of the milk powder, and replacing manual packaging to reduce labor costs, helping the client achieve large-scale, standardized production.

Saturday December-06 2025 15:34:11