Recycled carbon black powder packaging machine

The recycled carbon black powder packaging machine is an automated packaging machine used for metering, filling, and sealing recycled carbon black powder. It can accurately measure the recycled carbon black powder, reducing errors from manual packaging and ensuring consistency in the packaging of each bag. It can be used for recycled carbon black powder of different raw materials such as waste tires and waste plastics, with each bag containing 10-50 kg and a packaging speed of 20-60 bags per minute. Based on the characteristics of the recycled carbon black powder, waterproof and moisture-proof PE film or PP woven bags are generally selected for packaging, with styles including valve bags and open bags.

What are the classifications of recycled carbon black powder packaging machines?

Recycled carbon black powder packaging machines mainly come in three types: valve bag type, vacuum type, and integrated forming, filling, and sealing type. The choice of model varies depending on the specific packaging requirements of the recycled carbon black powder.

Valve bag type recycled carbon black powder packaging machines use a screw metering system to feed the recycled carbon black powder into a valve bag and automatically seal it. They can be used with a dust collection device to purify the dust, offering high metering accuracy (±0.1% - ±0.5%) and reducing material waste. Packaging speed is 30-60 bags per minute, with a packaging weight of 5-100 kg.

Vacuum-type recycled carbon black powder packaging machines use vacuum negative pressure to draw recycled carbon black powder into packaging bags while simultaneously expelling gas, and then seal the bags. They are commonly used for packaging ultrafine and nano-sized carbon black powders with high gas content and low specific gravity. High-compression vacuum packaging solves the packaging challenges of ultrafine powders, with a packaging speed of 50-70 bags/hour and a single bag weight of 5-50 kg.

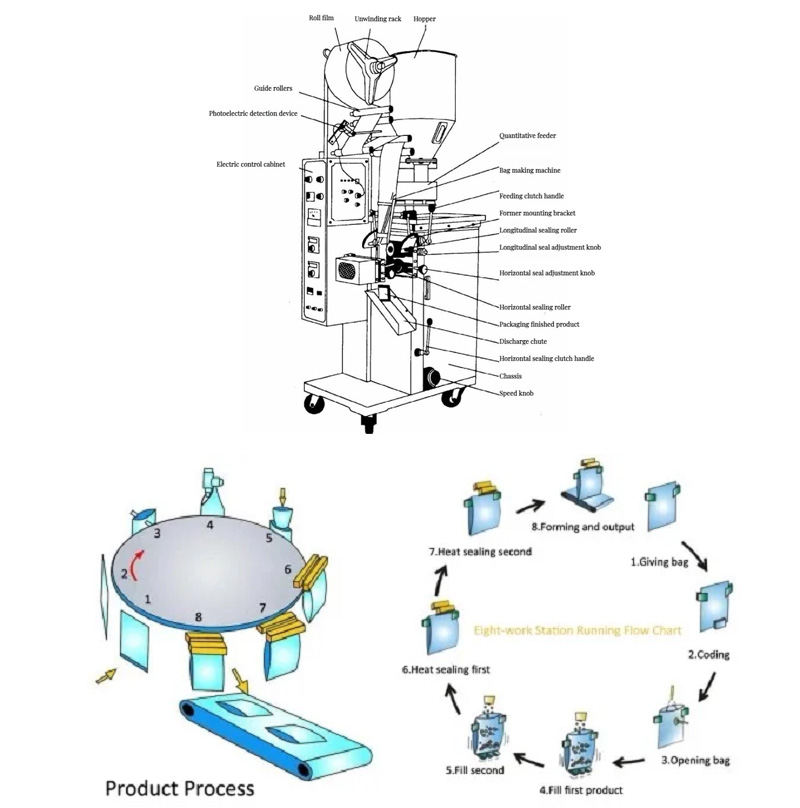

Integrated forming, filling, and sealing recycled carbon black powder packaging machines are used for recycled carbon black powders of varying flowability and fineness, allowing for flexible adjustments to packaging specifications. These automated packaging machines encompass the entire process of bag making, metering, filling, and sealing, minimizing manual intervention. Packaging speeds can reach 5-10 bags per minute, with each bag weighing 5-50 kg.

Recycled carbon black powder packaging machine video

What are the advantages of a recycled carbon black powder packaging machine?

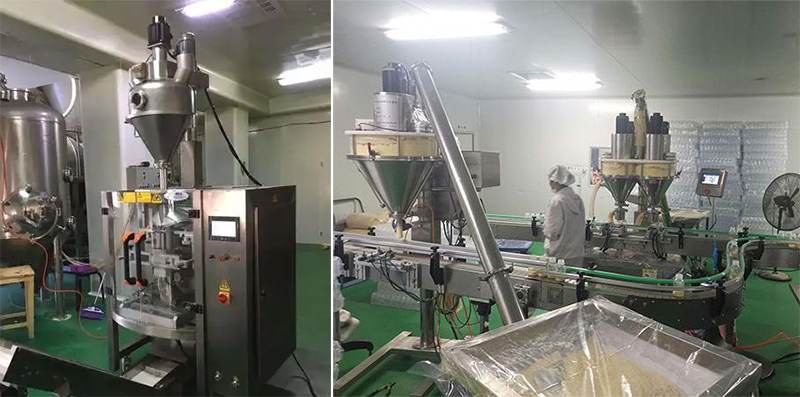

The recycled carbon black powder packaging machine is made of 304 stainless steel with a smooth inner wall, eliminating concerns about recycled carbon black powder adhering to the inner wall and reducing material waste. Since recycled carbon black powder dust is easily dispersed, the packaging machine uses a fully enclosed structure to minimize dust leakage, ensuring worker health and a clean working environment. Equipped with sensors and a weighing device, it can be freely adjusted to precisely control the packaging weight of each bag, supporting adjustments from 5-50kg per bag. It can package 20-60 bags per minute, suitable for small household use and large recycled carbon black powder processing plants. Customized configurations such as metering, bag size, and motor power can be customized according to different usage requirements.

How does a recycled carbon black powder packaging machine work?

When operating, the recycled carbon black powder packaging machine uses a screw feeder to transport recycled carbon black powder into the hopper of the metering device. The fully enclosed screw conveyor prevents dust from escaping. Sensors then capture weight data in real time to ensure accurate measurement. After metering, the recycled carbon black powder falls into customized packaging bags through a leak-proof discharge channel. The bag opening is sealed by heat sealing or sewing to prevent dust dispersion. The sealed, accurately weighed finished recycled carbon black powder is then transported to a designated storage area. The entire process is completed in a fully sealed state to prevent dust leakage.

Recycled carbon black powder packaging machine parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of a recycled carbon black powder packaging machine?

A recycled carbon black powder packaging machine is used for packaging finished materials in the recycled carbon black powder production process. It can be used in industries such as tire pyrolysis carbon black, plastics, building materials, chemicals, and metallurgy to package recycled carbon black powder of varying fineness, purity, and specifications, including granular carbon black powder, fine powder, and modified carbon black powder.

Recycled Carbon Black Powder Packaging Machine Customer Case

| Client Case Name | Packaging Materials | Packaging Quantity | Packaging Speed | Packaging Bag Material | Packaging Bag Dimensions (Length x Width x Height, Unit: mm) |

| Case Study of Recycled Carbon Black Packaging in a Rubber Products Factory | Recycled carbon black powder from waste tire pyrolysis, particle size D99=400-600 mesh, contains a small amount of impurities, medium flowability | Standard industrial packaging 25kg/bag, supports emergency adjustments to 10kg/bag | At 25kg/bag, 45-55 bags per hour; at 10kg/bag, 80-90 bags per hour | Outer layer PP woven bag (tensile strength ≥ 60MPa) + inner layer conductive PE film, surface resistivity ≤ 10⁶ Ω, anti-static design | 25kg bag: 550 × 350 × 120; 10kg bag: 400 × 250 × 100 |

| Battery-Grade Recycled Carbon Black Packaging Case Study of a New Energy Materials Company | Refined recycled carbon black powder, particle size D99=800 mesh, purity ≥99.5%, ultrafine light powder, prone to dust generation | High-precision small packaging 10kg/bag, fixed specifications with no adjustment required | 30-40 bags per hour, including vacuum compaction process (compaction density increased by 400%) | Aluminum foil/PET/PE composite film, thickness ≥150μm, built-in desiccant, anti-static shielding layer (surface resistance ≥10⁴ Ω) | 450×300×110 |

| Recycled Carbon Black Colorant Packaging Case Study of a Building Materials Factory | Recycled carbon black powder for construction, particle size D99=300 mesh, moisture content ≤0.5%, good flowability | Bulk packaging 500kg/bag, equipped with ton pallet transport | 8-12 bags per hour, including vibration compaction and automatic palletizing processes | High-strength PP woven ton bag (safety factor 6:1) + inner PE moisture-proof film, equipped with bottom unloading valve | 1200×1200×1500 |

| Packaging case of general-grade recycled carbon black from a recycling company | General-grade recycled carbon black powder, particle size D99=500 mesh, contains trace metal impurities, moderate flowability | Standard 20kg/bag, available in 25kg/bag and 50kg/bag sizes | 20kg/bag: 50-60 bags per hour; 50kg/bag: 20-25 bags per hour | Multi-layer paper-plastic composite bag (kraft paper + PE film + aluminum foil), water vapor transmission rate <0.2g/m²/day | 20kg bag: 500×320×110; 25kg bag: 550×350×120; 50kg bag: 650×400×150 |

Saturday November-29 2025 17:00:00