Tea Powder Filling and Sealing Machine

Tea powder filling and sealing machine is specifically designed to automate the packaging process of tea powder into containers, such as pouches, bags, or jars. These machines are commonly used in the tea industry to ensure efficient and accurate packaging of tea powder.

Live video

Application of tea powder filling and sealing machine

Various types of tea powder packaging: Ground matcha powder, granular instant tea powder, tea bag inner bag tea powder, milk tea powder, tea beverage powder, mixed powder that may contain a small amount of tea leaves

Food industry (powder materials): coffee powder, milk powder, spices, health products/pharmaceutical powder, cocoa powder, baking powder, food additives

Chemical industry: pesticide powder, laundry detergent, detergent powder, dye powder

What are the advantages of Tea Powder Filling and Sealing Machine?

1. High-precision filling: Advanced volumetric or gravimetric filling mechanisms are used to ensure consistent quantitative tea powder, minimize waste, and ensure uniformity of each package (e.g., accuracy of ±1%).

2. Speed and automation: Automated machines can fill 50-200 bags per minute (depending on the model), significantly improving productivity compared to manual methods.

3. Extended shelf life and freshness: Some machines integrate nitrogen flushing or vacuum sealing options to remove oxygen, prevent oxidation, and prolong the freshness and aroma of tea powder.

4. Diverse packaging formats: Supports strip packaging, sachet packaging, bag packaging or can packaging to meet different market needs (e.g., single-serving packaging or bulk packaging). Packaging format switching is usually fast, reducing downtime.

5. Hygienic and pollution-free: Made of food-grade stainless steel, it meets FDA/CE standards. The sealed design prevents external contamination, which is critical for organic tea or high-end tea brands.

What are the structures of Tea Powder Filling and Sealing Machine?

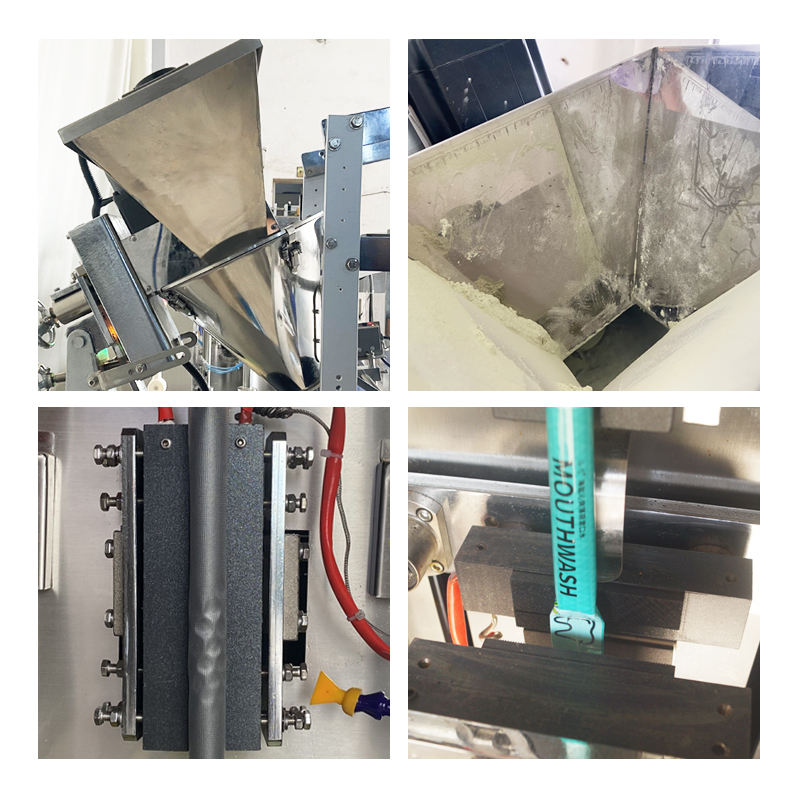

Analysis of the core structure of the Tea Powder Filling and Sealing Machine: This automated equipment consists of a feeding system (anti-powder jam hopper + precise screw filling), a packaging and forming module (vertical/horizontal bag making, optional nitrogen preservation), a heat-sealing cutter (multi-temperature zone control) and an intelligent center (PLC touch screen + photoelectric tracking). It completes metering-filling-sealing in 3 seconds, and its anti-static and antioxidant structure is designed to match the characteristics of tea powder, ensuring efficient and aseptic packaging from matcha to instant tea.

Tea Powder Filling and Sealing Machine Customer Case

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| Japanese matcha powder manufacturer-small dose matcha powder (for single brewing) | 2g/bag | 120 bags/minute (fully automatic assembly line) | 30mm × 50mm (slim tea stick packaging) | Aluminum foil composite film (moisture-proof + light-proof) + nitrogen filling for freshness preservation |

| Indian CTC tea powder exporter-500g family-sized instant black tea powder | 500g/bag | 40 bags/minute (weighing filling) | 150mm × 200mm (self-supporting zipper bag) | PET/AL/PE three-layer composite (UV protection + leakproof) |

| Chinese health tea brand (e-commerce small packaging track)-7 kinds of mixed herbal tea powder (1 week gift box) | 10g/bag × 7 bags/box | 80 packs/minute | 60mm × 80mm (matte texture color printing film) | Degradable PLA material (in line with EU environmental standards) |

When selecting a tea powder filling and sealing machine, consider factors such as production capacity, container size and type, accuracy requirements, and the specific characteristics of the tea powder being packaged. It's recommended to consult with suppliers or manufacturers who specialize in tea packaging machinery to ensure you choose a machine that meets your specific needs.

Wednesday September-03 2025 18:14:20