Fully Automatic Pouch Packing Machine

What is a Fully Automatic Pouch Packing Machine?

The Fully Automatic Pouch Packing Machine is a fully automated system for bagging materials, performing functions such as bag forming, material metering, filling, sealing, and printing. It can fully automate the packaging process for bulk powders, granules, liquids, and pastes, from bulk to finished bagged products, without manual intervention. It boasts a high packaging rate of 40-150 bags per minute, with packaging capacities ranging from small-volume products like 5g condiments to medium-volume products like 5kg flour. Bag sizes are adjustable, with widths ranging from 50-200mm and lengths from 80-300mm. Bag materials include polyethylene, polypropylene, and aluminum-plastic composite film, and support three-side seal, four-side seal, and back-seal packaging types.

Fully Automatic Pouch Packing Machine Video

What types of Fully Automatic Pouch Packing Machines are available?

Fully Automatic Pouch Packing Machines are designed to meet the needs of different materials, requiring different machine models. Depending on the type of material being packaged, they can be categorized into four types: granular, powder, liquid/paste, and special-purpose.

| Categories | Automatic Granule Bag Packaging Machine | Automatic Powder Bag Packaging Machine | Automatic Liquid/Paste Bag Packaging Machine | Special Shape Bag Packaging Machine |

| Pictures |

|

|

|

|

| Features | Precision metering devices such as screws or measuring cups prevent particle jams and leakage. Some models feature a vibration discharge function. | Dust removal and a sealed discharge channel prevent powder dust and provide high metering accuracy (±1%). | Piston or pump metering is employed with a drip-proof seal. Some models support heating and heat preservation (suitable for hot-melt pastes). | A wide discharge channel equipped with a photoelectric positioning or servo system accommodates irregularly shaped materials and prevents jams. |

| Packaging Volume | 5g–10kg | 3g–5kg, focusing on small-dose, high-precision packaging | 10ml–2L | Single Material Weight 5g–500g |

| Packaging Speed | 20–150 bags/minute | 15–120 bags/minute | 25–180 bags/minute | 10–80 bags/minute |

| Applicable Materials | Various granular materials, such as rice, nuts, coffee beans, plastic pellets, fertilizer granules, etc. | Fine powders or powdered materials, such as flour, milk powder, protein powder, pesticide powder, traditional Chinese medicine powder, etc. | Liquids (such as soy sauce, juice, disinfectant), pastes (such as toothpaste, facial cream, fermented soybean paste) | Block foods (such as biscuits, chocolate, braised eggs), special-shaped objects (such as small hardware, stationery, facial masks) |

What are the advantages of the Fully Automatic Pouch Packing Machine?

The Fully Automatic Pouch Packing Machine's primary advantage is improved packaging efficiency, reaching up to 150 bags per minute. It can operate 24 hours a day, reducing labor costs while ensuring consistent packaging volume. Product-contact surfaces are made of 304 or 316L stainless steel, making them hygienic and easy to clean, reducing the risk of cross-contamination. Flexible metering devices are available for packaging granules, powders, liquids, pastes, and irregularly shaped materials. Measuring accuracy is high, with an error control within 0.3%. Bag width and length can be adjusted according to needs. Equipped with a touchscreen PLC control system, the machine supports quick changes in bag specifications.

How does the Fully Automatic Pouch Packing Machine work?

When the Fully Automatic Pouch Packing Machine is in operation, the bag feeding mechanism automatically grabs pre-made bags from the hopper and transports them precisely to each workstation via a conveyor chain. The bag opener then uses a mechanical gripper to open the bag opening, while a positioning component ensures alignment. The corresponding metering and filling device then precisely injects the material into the bag, depending on the material type (granular, liquid, powder, etc.). After filling, the bag is conveyed to the sealing station, where it is sealed using methods such as heat sealing and ultrasonic sealing, and the date is printed. Finally, after cooling and setting, the finished bag is conveyed to the discharge port.

Fully Automatic Pouch Packing Machine Parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

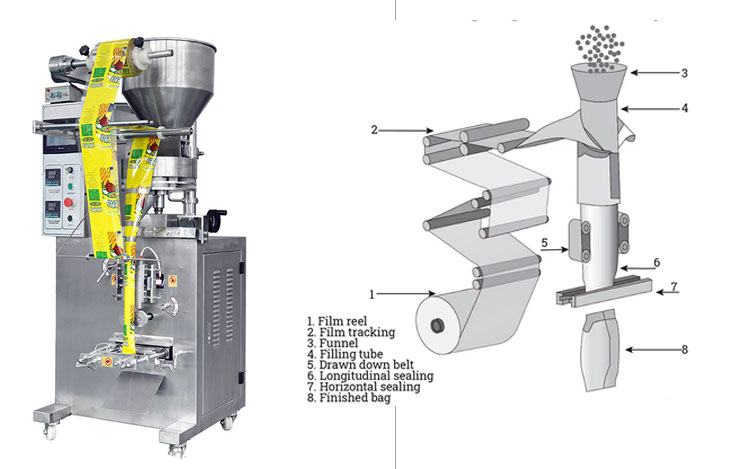

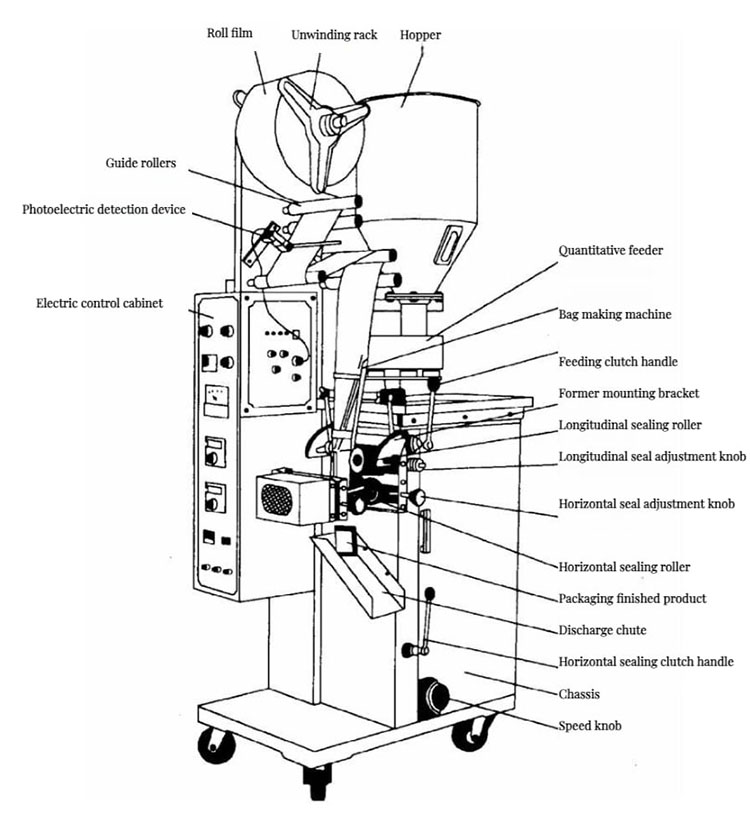

What are the components of a fully automatic pouch packing machine?

The fully automatic pouch packing machine primarily consists of an unwinding device, a forming system (using a forming tube or die to shape flat material into cylindrical or rectangular bags), a feeding system, a sealing system (using a heating block for heat sealing or an ultrasonic generator for ultrasonic sealing), a control system (a PLC control panel with a touchscreen for parameter settings), and a conveying and cutting system (which cuts the continuous stream of pouched products into individual packages and conveys them to the next process). These components work together to ensure smooth operation.

What are the applications of the Fully Automatic Pouch Packing Machine?

The Fully Automatic Pouch Packing Machine can be used in various industries to fully automatically package powders, granules, liquids, pastes, and irregularly shaped materials. For example, in the food industry, it's used to package chips, biscuits, rice, flour, soy sauce, salt, spices, dumplings, meat, and other products, ensuring food safety and extending shelf life. In the pharmaceutical industry, it's used to package cold medicine granules, capsules, and traditional Chinese medicine powders, ensuring precise dosage in each bag. In the agricultural industry, it's used to package seeds, animal feed, and fertilizers. In the chemical industry, it's used to package fertilizers, detergents, laundry powders, bath salts, and more, meeting the packaging needs of diverse industries.

How should I choose a Fully Automatic Pouch Packing Machine?

When selecting a Fully Automatic Pouch Packing Machine, you must first determine the form of the packaging material (e.g., granules, powders, liquids, blocks), and its properties (e.g., fluidity, corrosivity, specific gravity). Next, consider the required packaging volume per bag (5g-5kg available), the packaging speed (40-150 bags/min), the required bag size, the bag type (prefabricated bags or roll film, flat bags or stand-up bags, whether zippers are required, etc.), and the bag material (aluminum foil, PE, or paper-plastic composite). Only in this way can you choose a cost-effective machine.

Friday October-24 2025 17:27:05