Automatic Pouch Packing Machine for Masala

Automatic Pouch Packing Machine for Masala is an automatic packaging equipment specially used for masala and other seasoning powder products. This automatic bag packaging machine is efficient, accurate and reliable. It can realize the automatic metering, packaging and sealing of seasoning powder, improve production efficiency and ensure packaging quality. It is suitable for the production line of seasoning powder products.

Live Video

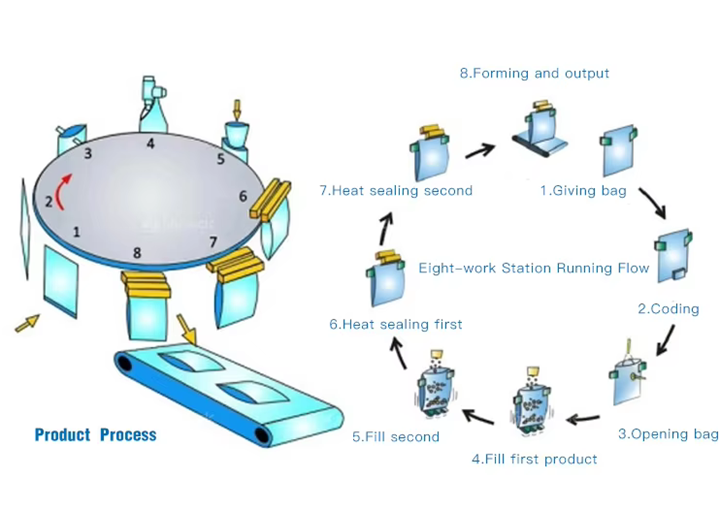

How does the Masala Automatic Pouch Packaging Machine work?

The packaging process of masala seasoning powder is to convey the powder to the metering device through a bucket feeder for accurate metering, and then convey it to the filling system for filling. The filled packaging bag is sealed by the sealing device to ensure the freshness of the product, while the control system monitors and controls the operation of the entire automated packaging process.

What products can be packaged with Masala automatic bagging machines?

Automatic Pouch Packing Machine for Masala can efficiently pack a variety of spice products, including but not limited to the following types:

Powdered Spices: Chili Powder, Turmeric Powder, Cumin Powder, Coriander Powder, Curry Powder.

Granular Spices: Black Pepper, Cumin Seeds, Fennel Seeds, Mustard Seeds.

Masala Blends: Garam Masala, Chai Masala, Tandoori Masala, Five-Spice Powder.

Other Seasonings: Dried Mint Leaves, Cinnamon Sticks, Bay Leaves.

What are the advantages of Masala automatic bag packaging machine?

Blazing Speed – Pack 10-60 pouches/minute (adjustable) – 3X faster than manual packing!

Pinpoint Accuracy – ±1% dosing precision – No waste, no underfilling!

Spice-Proof Design – Stainless steel (304) contact parts – Safe for turmeric, chili & all masalas!

Zero Contamination – Fully enclosed system – Keeps spices fresh & hygienic!

Smart Flexibility – Handles powders, seeds & blends – Switch spices in minutes!

Air-Tight Sealing – Optional nitrogen flushing – Extends shelf life by 2X!

Profit Booster – Cuts labor costs by 70% – ROI in <6 months!

Automatic Pouch Packing Machine for Masala Parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

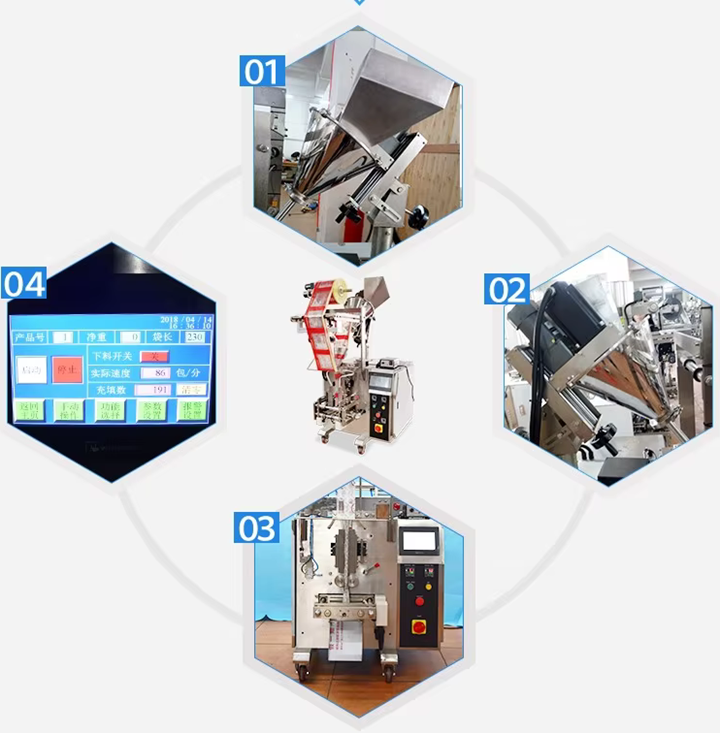

What is the structure of Automatic Pouch Packing Machine for Masala?

Bucket feeder: used to transport masala seasoning powder from the storage hopper to the packaging bag.

Measuring device: accurately measure the required amount of masala seasoning powder.

Filling system: fill the measured seasoning powder into the packaging bag.

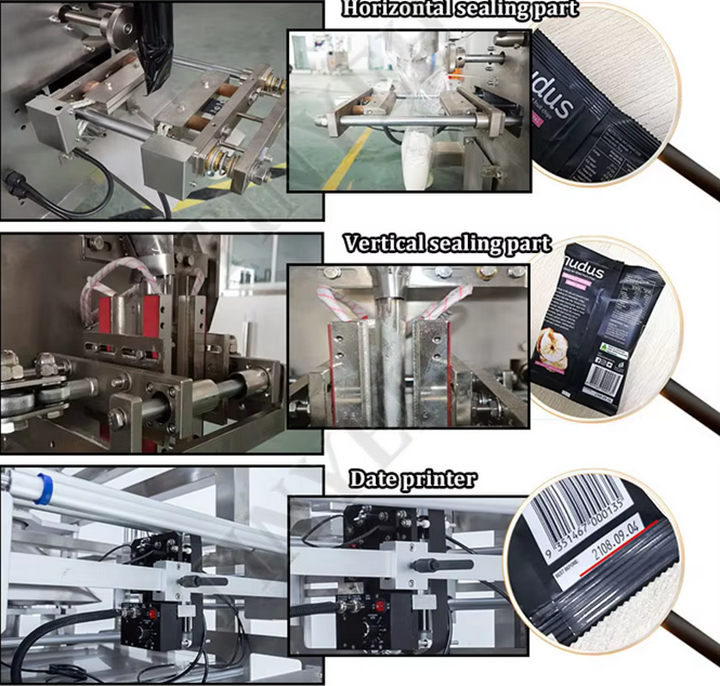

Sealing device: heat-seal or other sealing methods for the filled packaging bag.

Control system: an automated system used to control the entire packaging process

Automatic Pouch Packing Machine for Masala Customer Case

| Application scenario | Packing volume | Packing speed | Packing size |

| A small and medium-sized spice factory in India uses an automatic packaging machine to package Garam Masala mixed powder for retail channels (supermarkets/e-commerce). It needs to be moisture-proof, anti-caking, and maintain the flavor of the spice. | 50g-100g per bag | 30-45 bags/minute (semi-automatic model, manual bagging + automatic metering filling) | Width 80-120mm, height 150-200mm (standing bag, with zipper closure) |

| A Southeast Asian food company packages whole black pepper and cumin seeds for export to the European and American markets. High speed, no damage, and FDA compliance are required. | 200g-500g per bag | 60-80 bags/minute (fully automatic model, roll film bag making + filling + sealing integrated) | Width 150-200mm, height 200-300mm (four-side sealed flat bag, aluminum foil composite film) |

| A European organic brand packages high-end mixed spices (such as saffron + cardamom), which need to be vacuum sealed to extend the shelf life and maintain beautiful printing. | 10g-20g per bag (small boutique package) | 20-30 bags/minute (low-speed high-precision model, including vacuum pumping) | Width 60-80mm, height 100-150mm (triangular three-dimensional tea bag type, transparent window design) |

How to Choose Masala Automatic Pouch Packaging Machine?

Material characteristics analysis (determines the core configuration of the machine)

Powdered spices (such as chili powder, turmeric powder) → dust-proof spiral feeding system + anti-static device is required

Granular spices (such as cumin seeds, peppercorns) → vibrating feeder + anti-clogging design is required

Mixed spices (such as Garam Masala) → double spiral feeding is required to ensure uniform mixing

Oil-containing spices (such as sesame) → oil-resistant sealing strips and stainless steel heat sealing devices must be selected

Packing volume requirements (determines the machine model)

| Production scale | Recommended machine model | Daily output |

| Small workshop/trial production | Semi-automatic type | 500-2000 packages/day |

| Medium-sized processing plant | Standard automatic type | 5,000-20,000 packages/day |

| Large production line | Fully automatic line type | 50,000+ packages/day |

Packing speed (directly affects return on investment)

Economic type: 10-20 packages/minute → Suitable for start-up brands

Mainstream type: 30-50 packages/minute → Best price/performance ratio (90% of enterprises choose)

High-speed type: 60-120 bags/minute → Need to be used with automatic cartoning machine

Bag size (determines the machine station design)

Small bag (10-50g): requires high-precision micro-weighing scale (error ±0.5g)

Medium bag (100-500g): standard model can meet the requirements

Large bag (1-5kg): must be equipped with heavy-duty servo film pulling mechanism

Bag material (affects the choice of sealing system)

| Material type | Applicable spices | Sealing method required |

| Aluminum foil composite film | High-end retail packaging | Pulse + nitrogen replacement |

| PET/PE film | Economical large packaging | Constant temperature heat sealing |

| Stand-up bag | Supermarket channel | Four-side seal + bottom seal |

| Vacuum bag | Easily oxidizable spices | Vacuum pump + secondary seal |

Ultimate selection flow chart: Material testing → Determine bag type → Calculate production capacity → Select accuracy → Verify sealing → Test machine confirmation

Masala automatic bag packaging machine price

The price of a masala automatic bagging machine depends on several factors, including model, capacity, features, brand, supplier, region, and additional options. Prices range from a few thousand dollars to hundreds of thousands of dollars. The specific price needs to be determined based on your specific needs and requirements. If you need it, you can contact us directly and we can make a detailed quotation for your situation based on your detailed needs.

Thursday September-04 2025 16:32:37