Automatic Forming Powder for Filling And Sealing Machine

Automatic forming powder for filling and sealing machine, also known as VFFS packaging machine, is an efficient, high-quality and safe packaging equipment. Automatic Forming Powder for Filling And Sealing Machine is widely used in food, chemical, pharmaceutical, pesticide, feed and other industries, and is an important equipment for the production of powder products.

What are the types of automatic forming powder for filling and sealing machines?

| Classification | Vertical Automatic Forming Powder for Filling and Sealing Machine | Horizontal Automatic Forming Powder for Filling and Sealing Machine | Multi-Head Automatic Forming Powder for Filling and Sealing Machine |

| Features | Small footprint, suitable for factories or laboratories with limited space Integrated from bag making, filling to sealing, suitable for small batch production High precision: servo motor control, powder filling accuracy can reach ±1% |

Large-capacity production: mostly used in industrial assembly lines, high stability Long bag type support: customizable long strip packaging (such as 10-30cm strip bags) |

Ultra-high efficiency: multi-station synchronous operation (common 4-12 heads), doubling production capacity Intelligent packaging: each head can independently adjust the dosage, suitable for mixed formula powder Flexible switching: quick change of packaging specifications through PLC control |

| Packaging speed | Low-speed type: 20-40 packs/minute (suitable for high-precision medicines and health products) | Standard type: 60-100 packs/minute (general industry) | 4-head type: 150-200 packs/minute |

| High-speed type: 40-60 packs/minute (general food, chemical powder) | Ultra-high-speed type: 100-150 packs/minute (large food, daily chemical enterprises) | 8 heads and above: 300-500 packs/minute (industry top speed) | |

| Packing volume | Small capacity: 1g-50g (such as coffee powder, medicine) | Medium and large: 100g-2kg (such as laundry detergent, protein powder) | Small to medium capacity: 1g-200g (such as instant beverages, medicine powder packaging) |

| Medium capacity: 50g-500g (such as seasonings, milk powder) | Customization: support for oversized packaging (special molds required) | Support for parallel production of multiple specifications (such as sample packs of different weights) | |

| Application scenarios | Small and medium-sized enterprises, laboratories, high value-added powders (such as medicines, high-end foods) | Large-scale production, heavy industrial powders, areas requiring long bags (such as building material additives) | Ultra-large volume demand, e-commerce small packaging (such as tea bags, meal replacement powders), pharmaceutical subcontracting |

What is the use of automatic forming powder for filling and sealing machine?

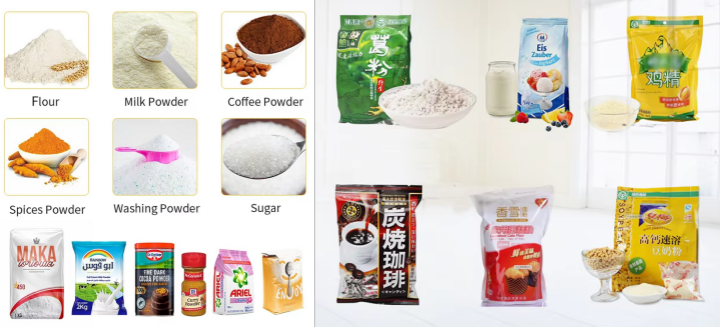

Food industry: Automatic powder forming, filling and sealing machines can be used to package various food powders, such as coffee powder, tea powder, milk powder, seasoning powder, flour, etc.

Pharmaceutical industry: In the pharmaceutical industry, automatic powder forming, filling and sealing machines are used to package various medicinal powders, such as herbal powder, medical powder, health care powder, etc.

Cosmetics industry: cosmetic powders, mask powders, loose powders and other products.

Agrochemical industry: pesticide powders, fertilizer powders and other agrochemical products.

Other industries: chemical industry, building materials industry, etc., for packaging powdered chemical products, building materials, etc.

Live video

What is the process of automatic forming powder for filling and sealing machine?

The automatic forming powder filling and sealing machine is an automatic packaging equipment that integrates automatic forming, filling and sealing functions, and is specially used to handle the packaging process of powder products. This equipment completes the packaging of powder products quickly and efficiently through a series of steps, including raw material supply, forming, filling, sealing, testing and inspection, as well as labeling and packaging.

What are the advantages of automatic forming powder for filling and sealing machine?

Lightning-fast packaging: Machines can fill and seal 20 to 500+ bags per minute, depending on the model (vertical, horizontal, or multi-head).

Milligram-level accuracy: Ensures consistent weight (±1% tolerance), crucial for pharmaceuticals and high-value powders.

Dual feeding system: Combines coarse & fine dosing for speed and accuracy.

Touchscreen PLC systems: Easy setup, adjustable parameters (bag size, speed, fill weight).

Closed-system design: Minimizes powder spillage, protecting workers from respiratory hazards.

Automatic forming powder for filling and sealing machine parameters

| Model | JS-420F | JS-520F | JS-620F | JS-720F |

| Packingmaterial | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE |

| FilmWidth | Max.420mm | Max.520mm | Max.620mm | Max.720mm |

|

Bag

Length

|

80-300mm | 80-350mm | 90-450mm | 100-500mm |

| BagWidth | 50-200mm | 80-250mm | 170-300mm | 180-350mm |

| Film RollDiameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| PackingSpeed | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-55bag/min |

| Power | 220V 50/60HZ 2KW | 220V 50/60HZ 3KW | 220V 50/60HZ 3KW | 220V 50/60HZ 3KW |

| Dimension | (L)1217*(W)1015*(H)1343MM | (L)1150*(W)1795*(H)1650MM | (L)1150*(W)1795*(H)1650MM | (L)1800*(W)1250*(H)1780M |

| Netweight | About540kg | About 600kg | About700kg | About750kg |

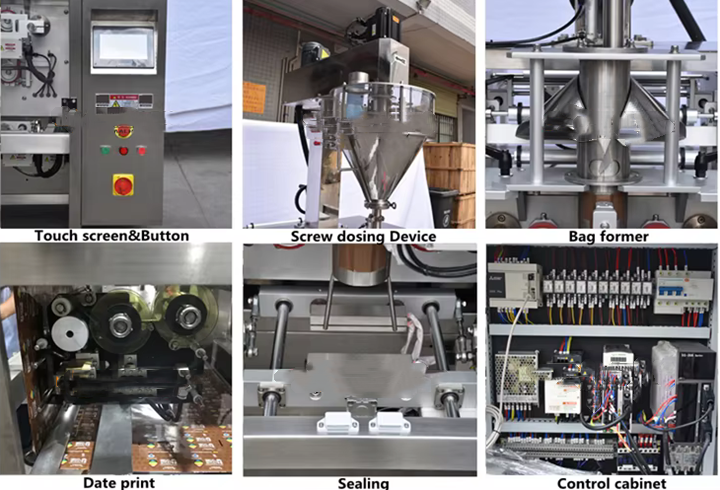

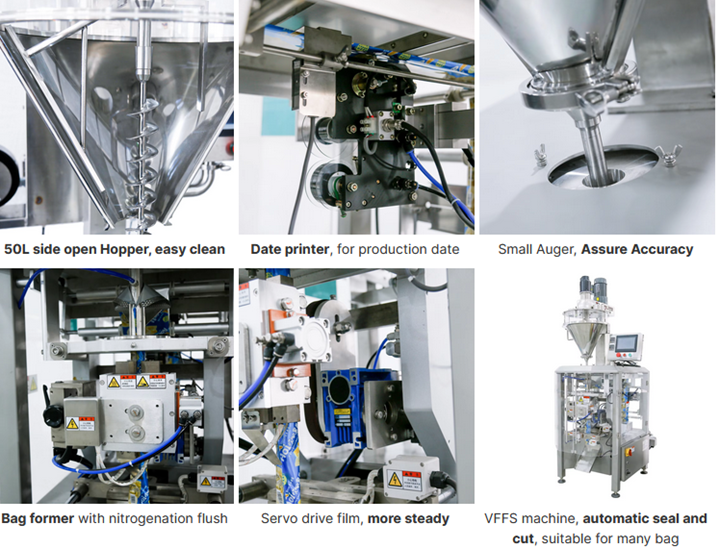

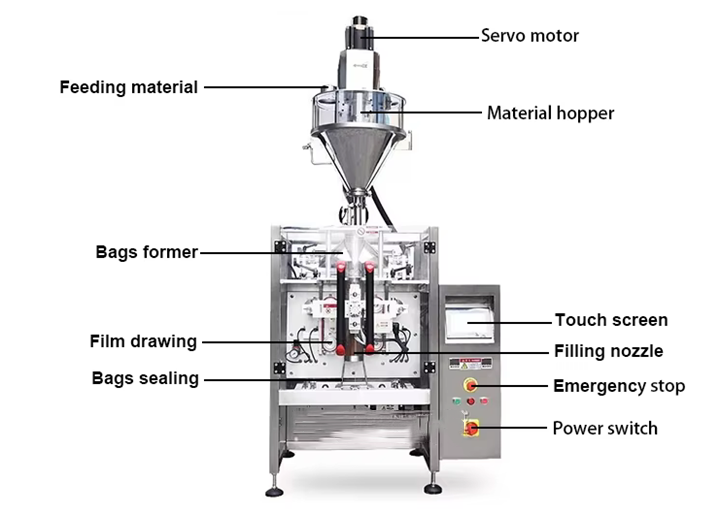

What are the structures of automatic forming powder for filling and sealing machine?

The structure of the automatic powder forming filling sealing machine usually includes raw material supply system, forming device, filling device, sealing device, control system and detection and inspection system. This structure enables the automatic powder forming filling sealing machine to achieve efficient, accurate and stable powder packaging process.

Automatic forming powder for filling and sealing machine Customer site

| Application scenario | Packaging volume | Packaging speed | Packaging size | Packaging bag material |

| Infant milk powder manufacturers require high-precision measurement and aseptic packaging. | 200g/bag | 50 bags/minute | L=150mm × W=100mm (stand-up bag with zipper) | Multi-layer composite film (PET/AL/PE), moisture-proof and anti-oxidation |

| Specialty coffee brand, small bags and portable packaging | 10g/bag | 70 bags/minute | L=80mm × W=60mm (back seal bag, easy-tear design) | Aluminum foil composite film (light-proof, fresh-keeping) |

| Pharmaceutical companies, need to meet pharmaceutical-grade cleanliness standards | 1g/bag (micro-dose high-precision packaging) | 30-40 bags/minute | L=50mm × W=30mm (small bag back seal, easy to tear) | Medical grade composite film (PET/PE, high temperature sterilization resistant) |

The automatic powder forming filling sealing machine uses advanced technology and automation devices to improve the packaging efficiency, accuracy and consistency of powder products, while ensuring the quality and sanitation and safety of the products. If you are interested in this equipment and want to learn more or make a purchase, please feel free to contact us. We will wholeheartedly provide you with professional consulting services and quotations to help you choose the appropriate automatic powder forming filling sealing machine. Looking forward to working with you!

Thursday September-04 2025 16:22:44