What is a Vertical Packaging Machine for condiments?

A Vertical Packaging Machine for condiments is an automated packaging machine used for various condiments. It automates the bag-making, precise metering, filling and sealing, and printing and coding processes for condiments in powdered, paste-like, and granular forms. It can pack 30-150 bags of condiments per minute, with bag weights ranging from 5g to 1000g. We support a variety of bag types, including back-seal bags, three-side-seal bags, pillow bags, and pin bags.

The Vertical Packaging Machine for condiments is constructed of 304 or 316L stainless steel, which is waterproof, rust-resistant, and corrosion-resistant, meeting food safety standards and ensuring hygienic safety during the condiment packaging process. Bag materials include PE, PP, aluminum-plastic composite film, aluminized film, and paper-plastic composite film. We can also provide customized solutions based on the product, bag type, and bag material of your condiment.

What types of Vertical Packaging Machine for condiment are there?

Vertical Packaging Machine for condiment can be divided into three types according to the type of condiment to be packaged: powder, granular, and liquid/paste. You can choose the appropriate model according to your needs.

Vertical Packaging Machine for Condiment Granules: This machine utilizes "vibration feeding + twin-screw metering" to prevent granule jamming. When packaging 10g-5kg, the metering error is ≤1%. For example, when packing 500g of salt, the error per bag is no more than 5g, minimizing material waste. The heat-seal width of the bag opening is ≥8mm, and the bag leakage rate is less than 0.1%. It can be used to package salt, sugar, MSG, and peppercorns.

Powder Vertical Packaging Machine for Condiment: A fully enclosed feeding channel prevents powder from flying (complying with food hygiene standard GB 14881). A "spiral feeding + negative pressure feeding" system solves the bridging problem of fine powders (such as 80-mesh pepper powder). When packaging 0.5g-1kg, the machine can achieve speeds of 60-90 bags/minute. It is commonly used for packaging pepper powder, cumin powder, five-spice powder, flour seasoning packets, instant noodle seasoning packets, etc.

Liquid/Paste Vertical Packaging Machine for Condiment: Utilizing a 304 stainless steel piston feeder and a Teflon-coated interior, the machine prevents contamination. The discharge port features an automatic scraper and hot air filter to prevent dripping and contamination of the bag opening. Suitable for packaging soy sauce, oyster sauce, chili sauce, ketchup, and salad dressing, the machine boasts a sealing pass rate of ≥99.5% for packages ranging from 100g to 5L, extending shelf life by 3-6 months.

What are the advantages of a Vertical Packaging Machine for condiments?

The Vertical Packaging Machine for condiments utilizes a high-precision metering system, achieving a dynamic weighing error of ≤±0.2% and a powder packaging accuracy of ±0.1%-0.5%, effectively reducing material waste. It can pack up to 150 bags per minute (depending on the material state and package weight), improving production efficiency. It accommodates multiple packaging specifications, easily meeting the packaging requirements of different condiments, and can quickly switch production lines within 15 minutes. Its fully enclosed structure and pulse dust removal device ensure dust emission is less than 1mg/m³, meeting food safety production standards.

How does the Vertical Packaging Machine for condiments work?

When operating, the metering system automatically dispenses condiments according to preset weight or volume. A film-pulsing mechanism pulls the film roll into the former to form the bag. The condiments are then placed into the pre-formed bag through the feed port. The bag is then sealed with longitudinal and transverse sealing systems and cut into individual bags.

Vertical Packaging Machine for condiment specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of the Vertical Packaging Machine for condiments?

The Vertical Packaging Machine for condiments can package all types of condiments, including powders, granules, and pastes:

Powdered seasonings: chili powder, pepper powder, five-spice powder, thirteen-spice powder, curry powder, garlic powder, onion powder, chicken powder, seafood powder, MSG, chicken bouillon, powdered sugar, vanilla powder, lemon powder, cumin powder, etc.

Sauce seasonings: cooking sauce, hot pot sauce, baked salad dressing, fruit sauce, edible jam, peanut butter, spicy sauce, tomato sauce, sesame paste, sweet noodle sauce, etc.

Granular seasonings: chicken bouillon, MSG, granulated sugar, sesame seeds, poppy seeds, and other small granules

Compound seasonings: blended seasonings, marinade powder, hot and sour powder, coffee powder, tomato powder, fish sauce powder, etc.

What are the types and materials of packaging bags for the Vertical Packaging Machine for condiments?

The Vertical Packaging Machine for condiment supports a variety of bag types and materials to meet the packaging needs of different products:

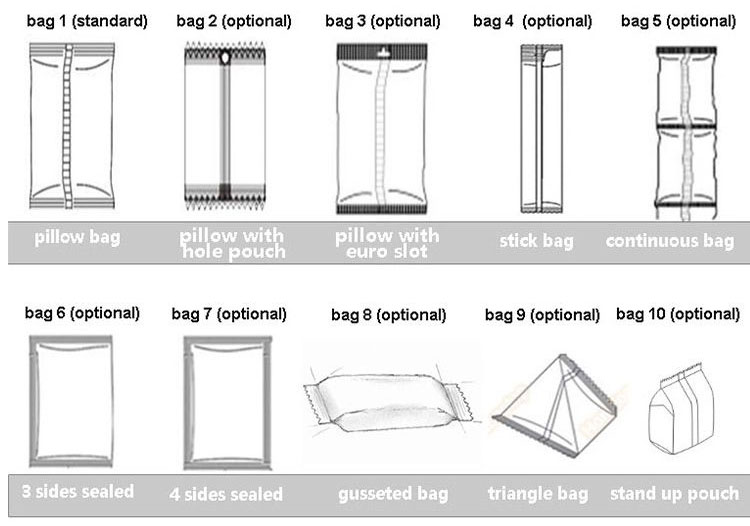

Packaging bag types: Pillow bags, pin bags, perforated bags, tote bags, box bags, stand-up pouches, zipper bags, slant-slot stand-up pouches, flat bags, etc.

Packaging bag materials: PE composite film, aluminum foil film, aluminized film, and other composite films; kraft paper laminated bags, woven bags, plastic bags, etc.

Sealing methods: Supports a variety of sealing methods, including three-side seal, four-side seal, and back seal.