What is Vertical Packaging Machine for Liquid Sauce?

The vertical packaging machine for liquid sauce is an automated packaging equipment designed for viscous, semi-fluid and paste sauces (such as ketchup, salad sauce, chili sauce, oyster sauce, etc.). It can quickly complete the packaging of sauces from raw materials to finished products, avoid pollution and waste caused by manual operation, and ensure food safety. The packaging speed can usually reach 30-140 bags per minute, and the packaging volume can be set according to demand, with a common range of 50-500 grams/bag. It supports a variety of packaging bag types such as three-side sealing and four-side sealing. The packaging material is mostly food-grade composite film (such as PET/PE, PA/PE), which has moisture-proof, anti-oxidation and heat-sealing properties. The packaging size is flexible and adjustable, which can adapt to bags of different specifications, and is widely used in food processing, condiment production and other industries.

What types of Vertical Packaging Machine for Liquid Sauce are there?

Vertical Packaging Machine for Liquid Sauce has three models: low viscosity, medium viscosity and high viscosity. You can choose according to the viscosity of the sauce and packaging requirements:

Low viscosity Vertical Packaging Machine for Liquid Sauce: Suitable for sauces with good fluidity such as salad dressing, seasoning oil, soy sauce, etc., using a pump metering system, the packaging speed can reach 60-140 bags/minute.

Medium viscosity Vertical Packaging Machine for Liquid Sauce: Designed for ketchup, chili sauce, jam, etc., equipped with a piston filling system, packaging speed 40-80 bags/minute, metering accuracy ±1%.

High viscosity Vertical Packaging Machine for Liquid Sauce: For thick materials such as peanut butter, sesame paste, hot pot base, etc., a special pressurization system is used to ensure smooth filling, packaging speed 20-50 bags/minute.

What are the advantages of Vertical Packaging Machine for Liquid Sauce?

Choosing our Vertical Packaging Machine for Liquid Sauce will give you the following significant advantages:

High-precision metering: Using imported servo control system, the metering accuracy can reach ±0.5%, effectively reducing the waste of sauce.

Efficient production: The maximum packaging speed can reach 140 packs/minute (depending on the product characteristics), greatly improving production efficiency.

Wide adaptability: It can handle a variety of sauces from thin to highly viscous, including but not limited to ketchup, chili sauce, peanut butter, sesame paste, hot pot base, salad dressing, etc.

Hygienic design: All parts in contact with the material are made of stainless steel, which meets food hygiene standards, and some models support waterproof flushing design.

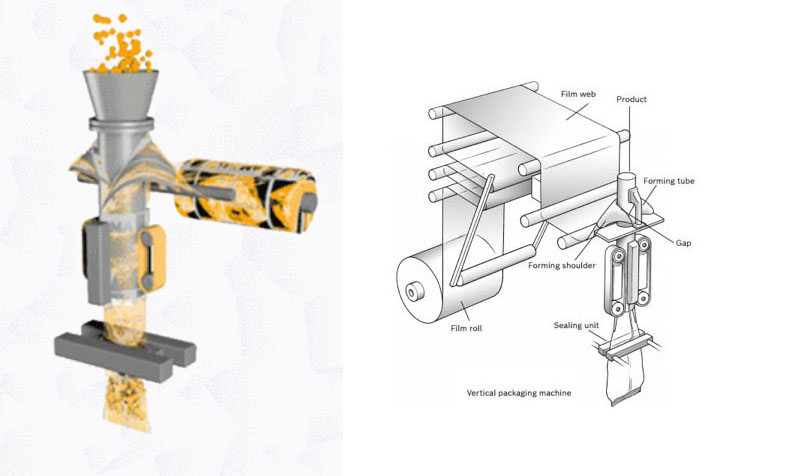

What is the principle of Vertical Packaging Machine for Liquid Sauce?

The packaging process of Vertical Packaging Machine for Liquid Sauce is as follows: the roll packaging film is pulled into the former, rolled into a tube and then heat-sealed longitudinally into a bag; the sauce is injected into the bag through the filling head according to the set amount by the metering pump; the bag mouth moves to the horizontal sealing device with the conveyor belt to complete the sealing and cutting; the finished bag falls and is output. During the process, the photoelectric sensor locates the color mark in real time to ensure that the bag length is aligned with the pattern, and each link is synchronized to achieve fully automated operations from bag making, filling to sealing.

Vertical Packaging Machine for Liquid Sauce Parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What are the applications of Vertical Packaging Machine for Liquid Sauce?

Vertical Packaging Machine for Liquid Sauce can package a variety of sauces, including liquid sauces (such as ketchup, salad dressing, oyster sauce, commonly used in catering seasoning and food processing), semi-liquid sauces (such as chili sauce, bean paste, peanut butter, suitable for home cooking and condiment retail), paste sauces (such as hot pot base, sesame paste, honey, commonly used in hot pot ingredients and baking raw material packaging), and mixed sauces containing particles (such as mushroom sauce, beef sauce, which need to be equipped with anti-clogging filling heads). It has a wide range of application scenarios. It is used in food processing plants for large-scale production of finished sauces; condiment companies use it for small bag packaging before bottling; provide customized seasoning packages in the catering supply chain; some e-commerce brands also use it for portable packaging of Internet celebrity sauces to meet the needs of multiple scenarios such as retail, catering, and OEM.

Vertical Packaging Machine for Liquid Sauce Selection

Vertical Packaging Machine for Liquid Sauce is suitable for a variety of packaging materials and bag types, fully meeting the needs of various sauce products. In terms of packaging materials, we provide composite films such as PET/AL/PE and NY/PE, which have high barrier properties and effectively extend the shelf life of sauces; single-layer films such as BOPP/PE and CPP are economical and meet conventional packaging needs; we also provide environmentally friendly materials such as PLA degradable films and non-woven fabrics, responding to the trend of green packaging. In terms of bag selection, back-sealed bags are economical and efficient and are the mainstream in the market; three-side sealed bags are square in shape and have strong stability, suitable for high-end products; four-side sealed bags are fully sealed to protect easily oxidized sauces; special-shaped bags attract consumers with their unique appearance, and continuous bag packaging is convenient for combined promotions to enhance product competitiveness.

![[field:title/]](/uploads/250620/1-2506201522252C.jpg)