Vertical Form Fill Seal Packaging Machine

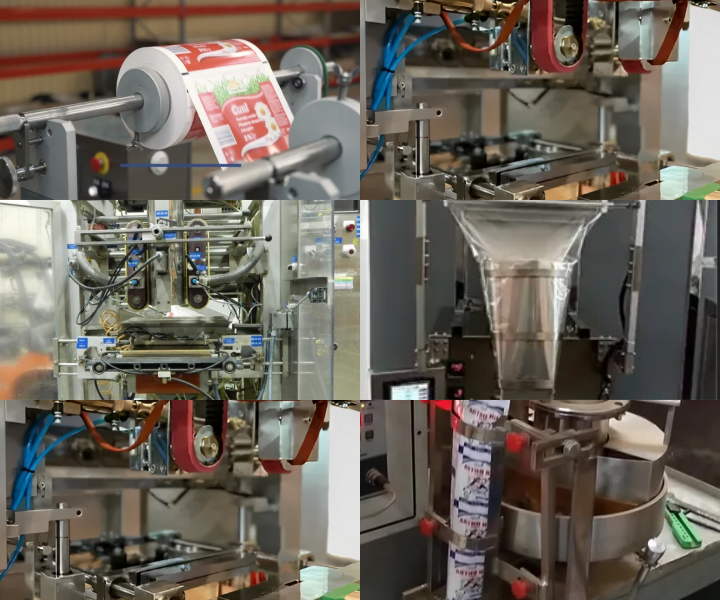

Vertical Form Fill Seal Packaging Machine , referred to as VFFS, is a common packaging machine, which is mainly used for automatic filling and sealing of granular, powdery, liquid and other materials.

What are the Categories of Vertical Form Fill Seal Packaging Machine?

Vertical form fill seal packaging machines can be divided into different types according to their movement mode and operation mode, including:

Semi-automatic: Automatic filling, manual bag placement and start.

Fully automatic: Automatic filling, sealing, and packaging – no manual operation. (Ideal for high-volume production, boosting efficiency and consistency.)

Intermittent: Filling and sealing occur in separate, stop-and-go steps.

Continuous: Filling and sealing happen simultaneously in a constant flow.

Vertical Form Fill Seal Packaging Machine Video

What industries are vertical form fill and seal packaging machines suitable for?

Food and beverage industry: such as juice, milk, salad dressing, condiments, coffee powder, sugar, etc.

Cosmetics and personal care products: such as shampoo, conditioner, shower gel, lotion, face cream, lipstick, perfume, etc.

Medical and pharmaceutical industry: vertical form fill and seal packaging machines are used to package medicines, health products, capsules, tablets, liquid medicines and other medical products.

Daily necessities industry: detergent, washing powder, paper towels, wet wipes, sanitary napkins, diapers, toothpaste, shampoo, shower gel, skin care products, cosmetics, etc.

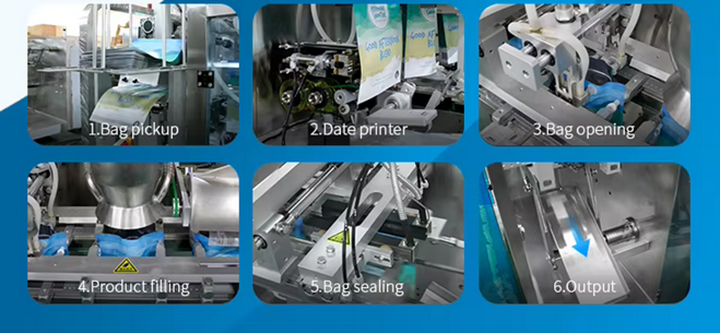

What is the principle of vertical form fill seal machine?

Feeding: The product enters the working area of the packaging machine through the feeding system.

Filling: Once the product enters the working area, the filling system will accurately inject the required product (such as liquid, powder, granular or solid) into the packaging bag.

Sealing: After filling, the top or side of the bag will pass through the sealing system for sealing. The sealing system usually uses heat sealing technology.

Cutting: After sealing, the packaging machine can perform a cutting operation to separate the sealed packaging bag into individual units. This can be achieved by a cutting knife, a cutter or other appropriate device.

Discharging: After cutting, the packaged product leaves the packaging machine through the discharging system and can be further labeled, boxed or other subsequent operations.

What are the advantages of vertical form fill seal machine?

Chinese and English screen display. PLC control, same service motor, very easy to operate.

Fully automatic bagging, filling, sealing, coding, conveying, counting can be completed in one operation, the most labor-saving equipment.

High-quality stainless steel, in line with GMP requirements, suitable for high-standard food packaging.

Horizontal and vertical temperature control, suitable for various mixed film, PE film packaging materials.

Pocket diversification, including four-seal bags and market-standard head bags. Conveniently integrated options, including zippers, tear holes, modified atmosphere packaging, one-way valve pressure applicators, etc.

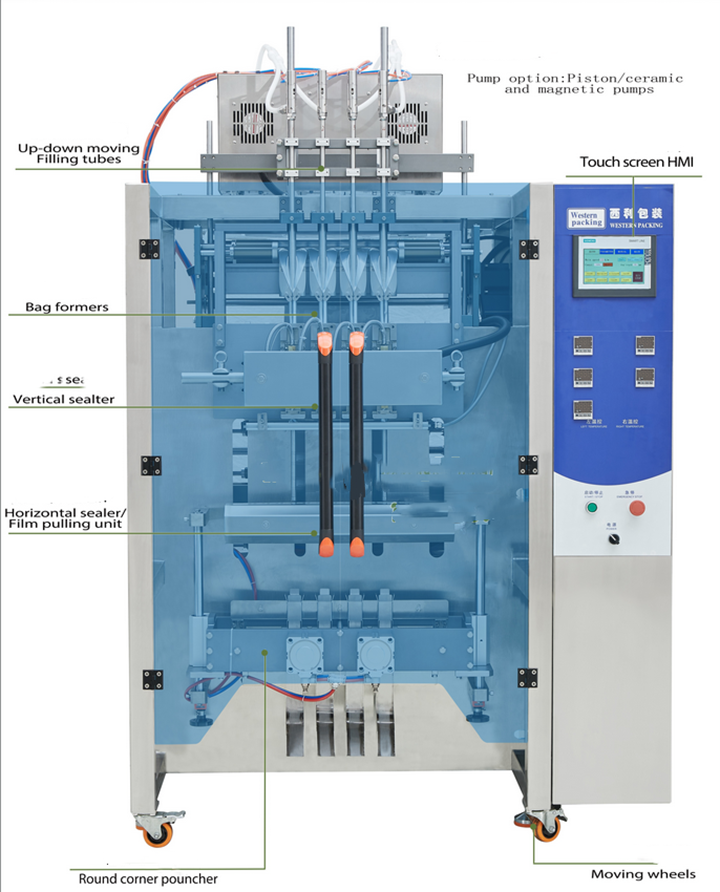

Vertical Form Fill Seal Packaging Machine Structure

Frame: The frame is the main supporting structure of the packaging machine and is usually made of solid metal materials.

Feeding system: The feeding system is used to introduce the product to be packaged into the working area of the packaging machine.

Filling system: The filling system is used to accurately inject the product into the packaging bag.

Sealing system: The sealing system is used to seal the top or side of the packaging bag.

Control system: The control system is used to monitor and adjust various parameters and operations of the packaging machine.

Sensors and safety devices: The packaging machine is usually equipped with various sensors and safety devices to monitor and protect the operation of the machine.

Discharging system: The discharging system is used to remove the packaged product from the packaging machine

What are the suitable bag types for vertical fill seal packaging machines?

Vertical Form Fill Seal Packaging Machine (VFFS) is suitable for packaging various types of packaging bags, including plastic bags BOPP, CPP, LDPE, HDPE, PET, paper bags, composite bags and other different materials, as well as various shapes such as flat bags, pillow bags, self-supporting bags, Doypack bags and zipper bags to meet the packaging needs of different products.

Vertical Form Fill Seal Packaging Machine Price

The price of a vertical form fill seal packaging machine is affected by many factors and generally ranges from $495.00 to $11,000.00. Packaging machines with different specifications and functions, well-known brands and high-quality manufacturers usually cost more. Market supply, demand and competition conditions also have an impact on prices. Customized configurations and additional equipment may increase the price of the packaging machine. If you have any needs, you can contact us directly and we will give you an accurate quotation and detailed product information.

Customer Cases

| Application scenario | Packing volume | Packing speed | Packing size | Packaging bag material |

| Large-scale potato chip automated packaging production lines require high-speed and stable weighing, filling and sealing of potato chips to meet market demand. | 50g/bag | 80 bags/minute | Width 150mm, length 220mm | Aluminum-coated composite film (PET/AL/PE) has good barrier and freshness preservation properties. |

| Small-dose packaging of granules of medical and health products has extremely high requirements on the sealing and hygiene of the packaging, and requires precise measurement and stable sealing. | 5g/bag | 60 bags/minute | Width 80mm, length 120mm | Composite film (PET/PE), with good sealing and moisture resistance, the inner layer meets the requirements of medical grade |

| Small-sized, single-use packaging of laundry detergent, which needs to be able to package liquid materials and ensure the sealing of the packaging to prevent leakage. | 30 ml per bag | 45 bags/minute | Width 100mm, length 150mm | PE composite film, with good corrosion resistance and sealing |

Why choose Dahan Vertical Form Fill Seal Packaging Machine manufacturer?

Dahan Vertical Form Fill Seal Packaging Machine manufacturer provides multiple series of VFFS packaging machines, including economical, high-speed and multi-functional customized models to meet different production needs. Support free machine trial, factory testing or remote video demonstration. After purchase, provide on-site installation and commissioning + operation training to ensure rapid production. Perfect after-sales service, including 1-2 years warranty, 24-hour technical support and fast supply of accessories. National delivery within 3-7 days, international customers support sea/air transportation, full logistics guarantee. 10 years of industry experience, 500+ customers trust, to provide you with cost-effective packaging solutions!

Thursday September-04 2025 16:27:16

Recommend Product

Related Information

- Vertical Form Fill Seal Powder Packaging Machine

- Vertical Form Fill Seal Packing Machines

- Rice for Automatic Weighing Filling And Sealing Machine

- What is a Vertical Form Fill Seal Packaging Machines?

- How do Vertical Form Fill Seal Packaging Machines Work?

- What is a Vertical Form Fill Seal Packaging Machines?

- How do Vertical Form Fill Seal Packaging Machines Work?