Pre-Made Bag Rotary Fill Seal Packaging Machine

Pre-Made Bag Rotary Fill Seal Packaging Machine used to automate the packaging process, which can complete the steps of filling, sealing and packaging of pre-made bags. It is suitable for different types of products such as powder, granular, liquid, etc. Pre-made bag rotary filling and sealing packaging machine is widely used in food, chemical, pharmaceutical and other industries, which helps to improve production efficiency and packaging quality.

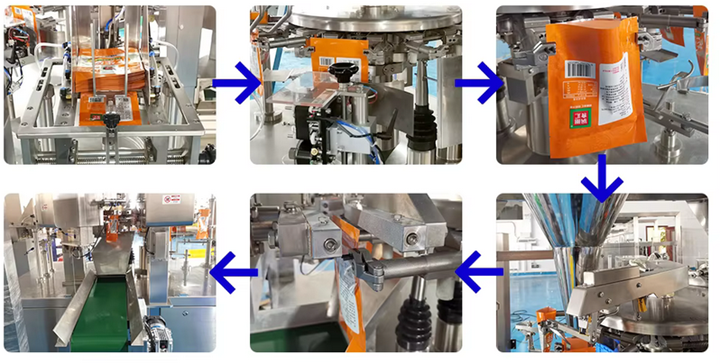

Customer site

How does the pre-made bag rotary fill and seal packaging machine work?

① Automatic bag feeding: Prefabricated bags (such as self-supporting bags and zipper bags) are accurately grabbed by vacuum suction cups or mechanical grippers and transferred to the rotating station. The bag mouth is automatically opened by the guide device to ensure smooth filling channels.

② Filling: According to the product type (granules, powders, liquids), servo screw metering, gravity filling or pumping system is used, with an accuracy of ±0.5%.

③ Gas Flushing (optional): Oxygen-sensitive products (such as nuts and milk powder) can be integrated with a nitrogen replacement system to extend the shelf life.

④ Sealing: The rotary multi-station design completes the bag mouth sealing by heat sealing knife or ultrasonic sealing.

⑤ Ejection: The finished bag is exported by the conveyor belt and can be connected to an automatic cartoning machine or labeling machine to achieve full production line operation.

Which industries are pre-made bag rotary filling and sealing packaging machines suitable for?

Pre-made bag rotary fill seal packaging machine has a wide range of applications in many industries and fields. The following are some common application areas:

-Food industry: can be used to package biscuits, candies, puffed foods, snack foods, frozen foods, etc.

-Chemical industry: can be used to package laundry detergent, detergent, pesticides, fertilizers, pigments, etc.

-Pharmaceutical industry: can be used to package medicines, powders, medical devices, etc.

-Pesticide industry: can be used to package insecticides, fungicides, herbicides, fertilizers, etc.

-Other industries: can be used to package hardware products, electronic components, toys, stationery, etc.

What are the advantages of pre-made bag rotary fill seal packaging machine?

High speed and high efficiency: The rotary design enables continuous operation, with a speed of 40-90 bags/minute517, far exceeding the linear packaging machine.

Precise control: PLC+touch screen system adjusts parameters (temperature, speed, filling volume) to adapt to different bag types and materials.

Flexible adaptation: It can handle prefabricated bags with a width of 80-300mm, and the materials include high barrier films such as PET/AL/PE and KNY.

Low failure rate: Equipped with automatic lubrication system and fault diagnosis module to reduce downtime

Pre-made bag rotary filling and sealing packaging machine parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Pre-made bag rotary filling and sealing packaging machine composition structure

The structure of the pre-made bag rotary fill and seal packaging machine can include the following main parts:

Bag supply system: used to provide pre-made bags and convey them to the filling area.

Filling system: used to accurately fill powder or granular materials from the hopper or feeding device into the pre-made bags.

Sealing system: used to seal the filled pre-made bags to ensure the sealing and freshness of the products. The sealing system usually adopts heat sealing technology, including heating elements, pressure devices, sealing knives, etc.

PLC control system: used to control the operation and parameter settings of the packaging machine.

Transportation system: used to transport the filled and sealed pre-made bags from the filling area to the packaging area or the next process.

Pre-made bag rotary fill seal packaging machine Customer Cases

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A well-known snack brand uses Pre-made bag rotary fill seal packaging machine to package potato chips, nuts and other puffed foods. | 50g-200g per bag | 60-80 bags/min (multi-station synchronous operation) | Bag width 80-150mm, height 120-220mm | PET/AL/PE composite film (moisture-proof, oxygen-barrier) |

| Pet food manufacturers use multi-station rotary packaging machines to package prefabricated zipper bags for consumers to use multiple times | 500g-2kg per bag (large-capacity packaging) | 50-70 bags/min (automatic bagging + filling + sealing) | Bag width 150-250mm, height 200-350mm | PET/PE (tear-resistant, easy-tear design) |

| The coffee processing factory uses Pre-made bag rotary fill seal packaging machine to produce prefabricated coffee bags to ensure sealing and extend shelf life | 10g-25g per bag (single brewing amount) | 40-60 bags/min (servo control precise measurement) | Bag width 60-100mm, height 80-150mm | KNY/PE (high barrier, anti-oxidation) |

Pre-made bag rotary filling and sealing packaging machine for sale

Pre-made bag rotary filling and sealing packaging machines have a wide price range, ranging from more than $10,000 for a basic model to $200,000 for a fully automated high-end system.

Entry-level equipment: about $13,000-15,500 per set

Mid-range models: $18,500-35,000 per set, with better stability and partial automation

High-end fully automatic systems: $100,000-350,000 per set, equipped with advanced features such as remote diagnosis and automatic lubrication

Ultra-high-speed professional models: some special models can cost more than $200,000 per set

Equipment price differentiation is mainly determined by the following factors:

Automation level: basic manual models are about $10,000-20,000, while fully automatic models equipped with automatic bag feeding, detection, and rejection systems can cost several times more

Production capacity: Models with speeds of 40-60 bags/minute are relatively low in price, and high-speed models with speeds of 80-100 bags/minute are usually 30-50% higher in price

Configuration options: Additional features such as remote diagnosis systems, automatic lubrication systems, and one-button bag clamping systems will increase costs

Customization requirements are also an important factor affecting prices. The price of standard models is relatively transparent, but if you need special bag processing, aseptic environment adaptation or special material contact parts, the price may increase significantly

Thursday September-04 2025 16:33:46