Food Packaging Machine for Candy

Food Packaging Machine for Candy are mechanical equipment specially used for packaging candy products.specially used for bagged packaging or container filling candy, including packaging hard candy or soft candy, packaging candy, candy glue, etc. Food Packaging Machine for Candy can adapt to different types of candy products, such as hard candy, soft candy, chocolate, etc., and can be packaged in a variety of forms, such as masala bags, folding packaging, box packaging, etc.

What are the types of Food Packaging Machine for Candy?

| Type | Applicable candy | Speed (pack/minute) | Packing volume | Best scenario | Features |

| Horizontal Food Packaging Machine for Candy | Round milk candy, square hard candy, button candy, special-shaped candy (such as oval, cylindrical, etc.) | 200-1200 | Large-scale continuous production | Large-scale candy factory, high-speed production line | Fully automatic three-side sealing, servo drive, ±0.5mm accuracy |

| Small vertical Food Packaging Machine for Candy | Granular candy (such as chocolate beans, soft candy), candied fruit, mixed packaging of nuts | 45-200 | Small and medium-sized batch flexible production | Fine candy, small-scale customization | Compact design, touch screen control, parameter storage |

| Multi-head weighing Food Packaging Machine for Candy | Irregular candies (such as gummy candies, marshmallows), mixed candies, quantitative weighing and packaging | 60-120 | High-precision weighing, range 12-1000g/bag | High-end gifts, healthy snacks | 16-24 head combination weigher, ±0.5g error, anti-sticking design |

Live Video

What are the applications of Food Packaging Machine for Candy?

Candy food packaging machines have a wide range of applications and can package various types of candies, including hard candies (such as flavored candies, mints, lollipops, chewing gum), soft candies (such as jelly candies, soft-hearted candies, fruit juice candies, coffee candies), chocolate products (such as chocolate beans, chocolate bars, chocolate fillings, chocolate sauces), candy beans (such as colored candy beans, fruit-flavored candy beans, and soft-hearted candy beans) and candy gift boxes. These packaging machines can meet the packaging needs of different types of candies, ensure that product packaging is accurate and beautiful, and enhance product competitiveness and market appeal.

Which Type of Packaging Is Best for Candy?

The most suitable packaging types for candies include pillow bags, plastic bags, flexible bags and mini cartons. Pillow bags are a common candy packaging form, especially suitable for Halloween and Easter. Plastic bags are simple and practical, and can show the appearance and color of candies. Flexible bags have fresh-keeping and moisture-proof functions, suitable for maintaining the freshness of candies. Mini cartons are high-end and exquisite packaging forms, suitable for the gift market and special occasions.

How does Food Packaging Machine for Candy pack candies?

The candy packaging process first requires the preparation of the candy, then the preparation of packaging materials, the selection of a suitable packaging format, the automatic packaging of the candy food in the packaging machine, the sealing and sealing, and the inspection and quality control.

What are the advantages of Food Packaging Machine for Candy?

1. Ultra-high-speed packaging, production efficiency increased by 50%+

The packaging speed can reach 200-1200 packs/minute, which is much higher than manual packaging. The automated assembly line runs 24 hours a day, reducing downtime. The electronic cam control is used to ensure packaging accuracy (±0.5mm) at high speed.

2. Accurate measurement, reduce waste

Multi-head weighing system: The error is only ±0.5g, ensuring the consistent weight of each package of candy, automatic correction of color labels, reducing packaging film waste, intelligent filling, avoiding manual weighing errors.

Touch screen control: One-click switching of packaging specifications, reducing manual adjustment time, Delta robot realizes automatic picking and placing, reducing manual intervention.

3. Improve product hygiene and safety

Fully sealed design, reducing dust pollution, stainless steel contact surface, easy to clean, avoiding cross contamination, and meeting FDA food grade standards.

Packaging machine parameters

| model | TCZB-250X | KN-320 tank | DS-320A |

| Bag type | pillow belt | pillow bag | back seal/3 side seal/4 side seal |

| Film width | 250mm | 320mm | 330-180mm |

| Packing speed | 40-230 bags per minute | 65 bags/minute | 30-80 bags/minute |

| Power | 220V, 50/60Hz,2.4kVA | 380V/50HZ 220V | 50/60Hz, 1.2kVA |

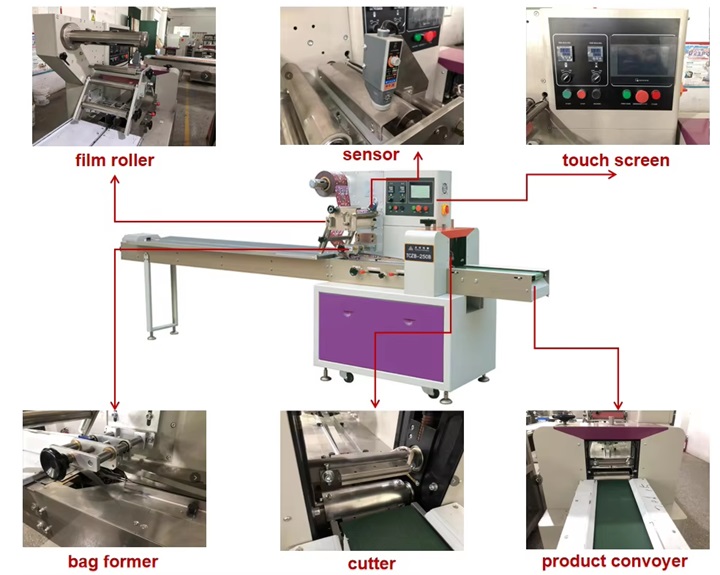

What are the structures of Food Packaging Machine for Candy?

Food Packaging Machine for Candys usually consist of a mechanical structure consisting of a feeding system, a metering system, a packaging system (such as sealing and sealing), a control system and a conveying system.

Food Packaging Machine for Candy Customer Cases

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A medium-sized candy company in Japan, packaging handmade soft candies of various shapes and flavors | 100-200g/bag | 40-50 bags per minute | 150 mm (width) x 200 mm (H) to 200 mm (W) x 250 mm (H) | High-quality, resealable stand-up pouches made of PET/PE laminate to ensure freshness and visual appeal |

| A large chocolate manufacturer producing standard-sized chocolate bars and multipacks | 50g/pack | 150-200 bars/minute | 150 mm (L) x 80 mm (W) | Printed BOPP film packaging |

| Chinese health tea brand (e-commerce small packaging track) - 7 mixed herbal tea powders (1 week gift box) | 10-30g/pack | 80-120 packs/min | 30-50 mm (W) x 80-120 mm (L) | Economical, heat-sealable OPP film |

How much does a Food Packaging Machine for Candy cost

The price of a Food Packaging Machine for Candy varies depending on a variety of factors, including the machine's specifications, features, production capacity, degree of automation, and supplier pricing. Generally speaking, a semi-automatic Food Packaging Machine for Candy may cost between a few thousand dollars and $10,000. Fully automatic Food Packaging Machine for Candys may cost from tens of thousands to hundreds of thousands of dollars. The specific price needs to be discussed and quoted in detail with the supplier based on specific needs and market research.

How to choose a Food Packaging Machine for Candy

Packaging products

What kind of candy are you packaging? Free-flowing granules (e.g. sprinkles), individual pieces (e.g. hard candy, chocolate), soft candy, powders, or mixed candies? The type of machine needs to match the shape and texture of your candy.

Granular/block candies (such as hard candies and chocolate beans): Vertical Form Fill Seal (VFFS) is often a cost-effective choice, with a multi-head weigher or measuring cup for fast speed and high precision.

Irregular shaped/fragile candies (such as soft candies and wafer biscuits): Horizontal Form Fill Seal (HFFS) can gently protect them from damage, and with a material processing line, the arrangement is more beautiful.

Liquid/paste candies (such as jam-filled candies): Liquid filling machines are required to ensure that the seal is leak-proof.

Packaging speed

Low speed (30-80 packs/minute): Suitable for start-ups or small-scale production.

Medium speed (80-200 packs/minute): Meets most candy production needs.

High speed (more than 200 packs/minute): Guarantees efficiency for large candy factories.

Packaging Bag Material

What type of packaging film or material will you use? Common options include OPP, CPP, PET, PE, foil laminates, and paper-based materials.

Make sure the machine is compatible with the sealing properties and thickness of the selected material. Some machines are better suited to specific types of film.

Consider barrier properties and shelf life requirements. If your candy is sensitive to moisture or oxygen, you need a machine that can seal and handle suitable barrier films.

Contact us for the best price

Henan Dahan Machinery Co., Ltd. has rich experience in the design, research, manufacturing and marketing of packaging machines. We enjoy a high reputation in the field of Food Packaging Machine for Candys, and our products are exported to many countries. Excellent quality and elegant appearance have won the favor of various countries. By providing high-quality products and services, we aim to help customers change their production and lifestyles and improve production efficiency.

We have the most advanced equipment and the most thoughtful service. In addition, by cooperating with us, you will get more than just the product itself. Welcome your inquiries, please feel free to contact us, we will reply you as soon as possible.

Wednesday September-03 2025 18:04:57