Chicken Seasoning Powder for Vertical Packaging Machine

Chicken seasoning powder has high requirements for the sealing, metering accuracy and dustproof performance of packaging equipment due to its small particles, easy moisture absorption and agglomeration, and poor fluidity. So how to solve this problem?

Our Chicken Seasoning Powder for Vertical Packaging Machine is specially used for vertical packaging equipment for granular condiments such as chicken essence and seasoning powder. Through the specially designed screw feeding system, nitrogen replacement device and anti-static treatment, it can efficiently complete the metering, bag making, filling, sealing, cutting and other fully automatic packaging processes to ensure that the chicken seasoning powder maintains the best quality from production to consumption. So compared with traditional horizontal packaging machines, what are the advantages of Chicken Seasoning Powder for Vertical Packaging Machine?

High space utilization: The vertical design occupies a small area, suitable for the compact production line layout of modern food factories

Excellent packaging accuracy: High-precision screw metering or electronic scale metering system is used to ensure that the weight error of each package of chicken seasoning powder is controlled within ±1%

Strong adaptability: It can handle the packaging needs of chicken seasoning powder of different specifications from 50g to 2000g to meet the diversified needs of the market

High hygiene standards: The parts in contact with the material are made of 304 stainless steel, which meets the food-grade hygiene requirements and avoids cross contamination

High degree of automation: From film roll forming to finished product output, it is fully automatic, which greatly reduces labor costs and improves production efficiency.

How Chicken Seasoning Powder for Vertical Packaging Machine Works?

The working principle of vertical packaging machine for chicken bouillon seasoning powder is to realize the packaging process of chicken bouillon seasoning powder through an automated process. First, the chicken bouillon seasoning powder is loaded into the hopper and accurately measured by the metering device. Then, the measured chicken bouillon seasoning powder is filled into the pre-prepared packaging bag through the filling device. Finally, the sealing device seals the packaging bag to complete the packaging process of chicken bouillon seasoning powder.

Chicken Seasoning Powder for Vertical Packaging Machine Parameters

| Model | Packing range | Packing speed | Bag size (width × length) | Power | Voltage | Weight |

| VFFS-420 | 100g-1kg | 25-70 bags/minute | ≤200mm × ≤300mm | 3.0kw | 220V 50Hz | 450kg |

| VFFS-520 | 200g-1.5kg | 25-70 bags/minute | ≤245mm × ≤350mm | 3.5kw | 220V 50Hz | 550kg |

| VFFS-620 | 500g-2.5kg | 20-60 bags/minute | ≤295mm × ≤400mm | 4.0kw | 220V 50Hz | 650kg |

| VFFS-720 | 1kg-5kg | 20-60 bags/minute | ≤345mm × ≤450mm | 4.5kw | 220V 50Hz | 750kg |

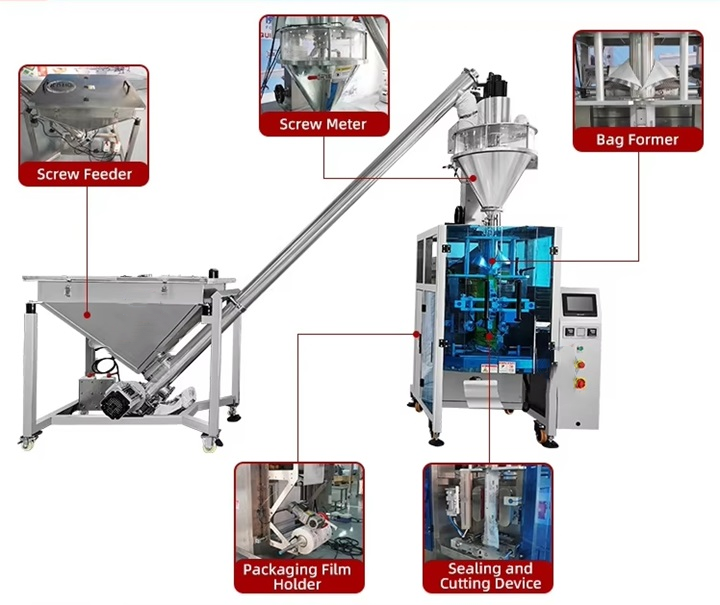

What are the structural components of Chicken Seasoning Powder for Vertical Packaging Machine?

1. Hopper: a feeding device for storing chicken bouillon seasoning powder.

2. Measuring device: accurately measuring the weight or volume of chicken bouillon seasoning powder.

3. Filling device: fill the measured chicken bouillon seasoning powder into the packaging bag.

4. Sealing device: seal the packaging bag filled with chicken bouillon seasoning powder.

5. Control system: control and adjust the operation of the packaging machine and the operation of each component.

What are the applications of Chicken Seasoning Powder for Vertical Packaging Machine?

Vertical packaging machine for chicken bouillon seasoning powder is widely used in food processing industry and condiment manufacturers for packaging granular condiments such as chicken bouillon, seasoning powder, soup stock powder, instant soup, etc. It is suitable for various packaging forms, such as pillow bags, triangle bags, three-dimensional bags, etc., which can meet different packaging needs.

Wednesday September-03 2025 17:59:47