Automatic Chocolate Bar Packaging Machine

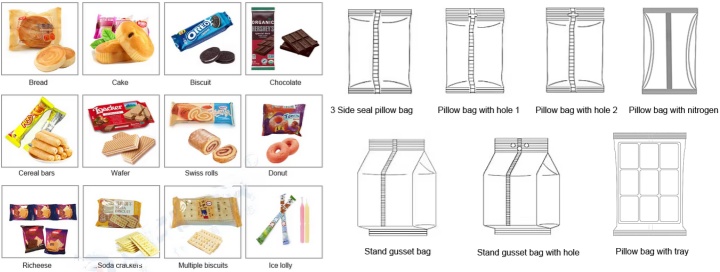

Automatic Chocolate Bar Packaging Machine can adapt to chocolate bars of different sizes and shapes, such as single packaging, multiple packaging, etc. It can quickly package a large number of chocolate bars to meet mass production needs and is widely used in chocolate bars, chocolate chips, chocolate candies and other chocolate products.

What are the categories of automatic chocolate bar packaging machines?

| Type | Core Features | Packaging volume | Speed | Applicable customers |

| Manual & Automatic Chocolate Bar Packaging Machine | Manual operation and automatic mode, suitable for small batch production or trial production stage; simple structure, easy to maintain; adjustable packaging parameters (temperature, speed, etc.). | 50~500 bars/h | Medium and low speed 10~15 bars/minute | Start-up, trial production |

| Automatic Chocolate Bar Packaging Machine for Home | Mini and silent, easy to operate | 100~300 bars/h | Low speed 5~10 bars/minute | Home workshop, handmade chocolate maker |

| Chocolate Bar Foil Wrapping Machine | Specially designed for aluminum foil/tin foil packaging to ensure airtightness; optional heat sealing or cold pressing methods to adapt to different chocolate types (such as meltable chocolate). | 300~800 bars/h | Medium and high speed 15~25 bars/minute | High-end chocolate brand and gift manufacturer |

| Small Chocolate Packaging Machine | Compact industrial machine, suitable for small and medium-sized chocolate factories, modular design, expandable (such as labeling machine, inkjet printer); adapt to a variety of chocolate shapes (flakes, blocks, special shapes) | 500~1,200 bars/h | High speed 20~30 bars/minute | Small and medium-sized food processing plants |

What industries are automatic chocolate bar packaging machines suitable for?

Confectionery & Chocolate Manufacturing: Mass production of milk/dark/white chocolate bars, filled chocolates, or specialty products (e.g., organic, sugar-free).

Food Processing & Snack Production: Packaging chocolate-coated snacks (e.g., granola bars, nuts) or composite products (e.g., chocolate with biscuits/cookies).

Health & Functional Foods: Protein bars, CBD-infused chocolates, or vitamin-enriched products requiring airtight packaging.

Gourmet & Artisan Chocolate Brands: Small-batch premium chocolates with custom shapes (e.g., hearts, geometric designs).

What are the advantages of automatic chocolate bar packaging machine?

High-speed packaging: Packs 200-500 bars per minute (vs. 30-50 bars manually), ideal for mass production, reducing labor costs by up to 70%.

Hermetic seal: Prevents oxidation and moisture intrusion, extends shelf life, and minimizes breakage (breakage rate <0.5%) for delicate or high-end chocolates.

Custom flexibility: Can handle a wide range of chocolate bar shapes (flat, square, round) and sizes (20-200 mm).

Food-grade materials: Stainless steel contact parts meet FDA, CE and ISO 22000 standards, and easy-to-clean surfaces prevent cross contamination.

How does the automatic chocolate bar packaging machine work?

First, the chocolate bars are transported to the packaging machine through the feeding system; then, the chocolate bars are positioned at the packaging position through the positioning system; then, the chocolate bars are packaged into finished products through the packaging system; finally, the packaged chocolate bars are transported out of the packaging machine through the conveying system.

Automatic chocolate bar packaging machine technical parameters

| Model | JS-420F | JS-520F | JS-620F | JS-720F |

| Packingmaterial | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE |

| FilmWidth | Max.420mm | Max.520mm | Max.620mm | Max.720mm |

|

Bag

Length

|

80-300mm | 80-350mm | 90-450mm | 100-500mm |

| BagWidth | 50-200mm | 80-250mm | 170-300mm | 180-350mm |

| Film RollDiameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| PackingSpeed | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-55bag/min |

| Power | 220V 50/60HZ 2KW | 220V 50/60HZ 3KW | 220V 50/60HZ 3KW | 220V 50/60HZ 3KW |

| Dimension | (L)1217*(W)1015*(H)1343MM | (L)1150*(W)1795*(H)1650MM | (L)1150*(W)1795*(H)1650MM | (L)1800*(W)1250*(H)1780M |

| Netweight | About540kg | About 600kg | About700kg | About750kg |

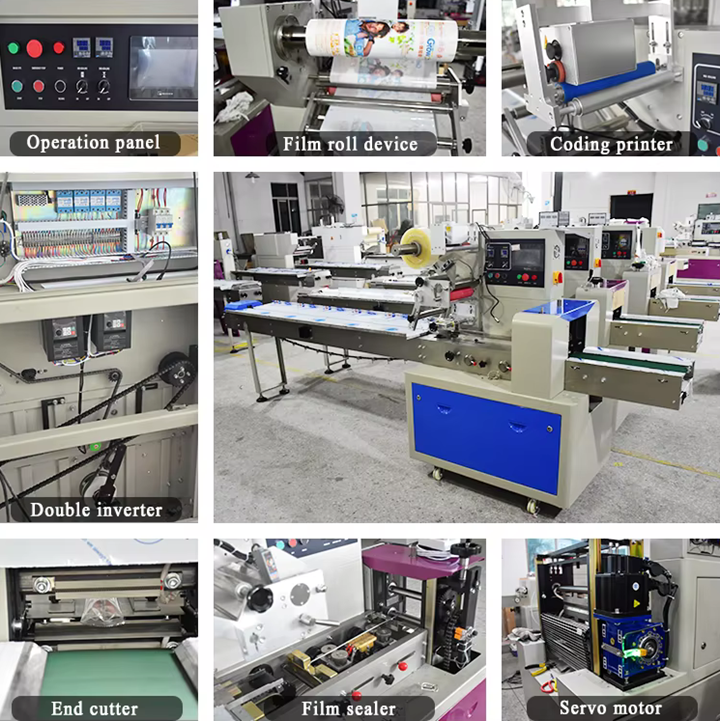

What are the structures of automatic chocolate bar packaging machine?

Feeding system: used to convey chocolate bars to the packaging machine.

Positioning system: used to position chocolate bars in the packaging position.

Packaging system: used to package chocolate bars into finished products.

Closing and sealing system: used to close and seal the packaging materials of chocolate bars to ensure the integrity and sealing of the packaging.

Control system: used to monitor and control the entire packaging process.

Conveying system: used to convey the packaged chocolate bars out of the packaging machine.

Customer Cases

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A high-end chocolate manufacturer in Europe produces single-row/double-row chocolate bars, which require fully automatic packaging to maintain product freshness and aesthetics. | Daily output 50,000 bars (8-hour work system) | 200-250 packs/minute | 120mm × 60mm (length × width) | Aluminum foil composite film (moisture-proof, anti-oxidation, extended shelf life) |

| An Asian food group produces chocolate bars with various flavors and needs to adapt to seasonal peak demand (such as Spring Festival and Valentine's Day) | 100,000 bars/day | 300 bars/minute | 200mm × 100mm | BOPP/PE composite film (high transparency, showing product appearance) |

| A North American organic chocolate brand, focusing on sustainable packaging, needs automated equipment to support biodegradable materials | 20,000 pieces/day | 80-120 packages/minute | 100mm × 50mm | PLA biodegradable film |

How much does automatic chocolate bar packaging machine cost?

The price of an automatic chocolate bar packaging machine varies depending on a variety of factors, including equipment model, production capacity, functional configuration, brand, and supplier. Prices range from $790.00 to $12,600.00. Simpler automatic chocolate bar packaging machines are usually cheaper and suitable for small-scale production or start-ups. High-performance, high-capacity automatic packaging machines are usually more expensive and suitable for large-scale production or companies with high production efficiency requirements. If you want to get accurate price information, you can contact our backend directly, and we will quote you based on your specific needs and requirements!

Thursday September-04 2025 16:24:05