Sachet Packing Machine for Powder

Sachet Packing Machine for Powder is an automatic packaging equipment specially used for packaging powder products. Through the automated operation process, sachet packing machine for powder accurately measures, packages and seals the powder materials in small bags for easy storage, transportation and sales. It is widely used in the automatic packaging of loose powder products in the food, cosmetics, medicine, health food, chemicals, agriculture and other industries, such as milk powder, beverage powder, pharmaceutical chemical powder, coffee powder, tea powder, spice powder starch and other materials.

What types of Sachet Packing Machine for Powder are there?

| Type | Description | Key Features | Best For | Example Models |

| Vertical Form-Fill-Seal (VFFS) Machines | Forms sachets vertically from a roll of film, fills with powder, and seals. | High-speed, customizable pouch sizes, servo-driven precision. | Food, pharmaceuticals, cosmetics. | Matrix MVA9, Winpack WP-20 |

| Horizontal Form-Fill-Seal (HFFS) Machines | Creates sachets horizontally, ideal for multi-lane or stick-pack formats. | Compact design, multi-compartment filling. | Coffee, spices, single-dose supplements. | Universal Pack horizontal models |

| 3-Side Seal Machines | Seals three edges (top, bottom, and side) for flat sachets. | Simple operation, cost-effective. | Small powder quantities (e.g., condiments, medicine). | QD-60C (Shanghai Qindian) |

| 4-Side Seal Machines | Seals all four edges for enhanced durability. | Better leak resistance, premium appearance. | High-value powders (protein, pharmaceuticals). | LD-320D (Landpack) |

| Back-Seal Machines | Seals along the back edge, with a fin-style closure. | Efficient for lightweight powders. | Tea, detergent, powdered supplements. | QD-60BF (Qindian) |

| Semi-Automatic Machines | Requires manual loading but automates filling/sealing. | Lower cost, suitable for small batches. | Startups, R&D labs. | FGJ-300 |

| Multi-Lane Machines | Simultaneously fills multiple sachets in parallel. | High throughput (100+ sachets/min). | Large-scale food/pharma production. | Matrix MVA12 |

| Auger-Filling Machines | Uses a screw mechanism for precise powder dosing. | ±0.5% accuracy, ideal for sticky/non-free-flowing powders. | Spices, flour, pharmaceuticals. | Universal Pack auger models |

| Pre-Made Pouch Fillers | Fills pre-formed pouches (no forming required). | Flexible for irregular shapes (stand-up pouches). | Premium products (cosmetics, nutraceuticals). | Viking Masek systems |

| Micro-Dosing Machines | Handles ultra-small powder quantities (0.1g–5g). | High precision, anti-static designs. | Medical doses, powdered additives. | JC-1A1 (Zhengzhou Aslan) |

Live Video

-

Washing powder packaging

-

Spice powder packaging

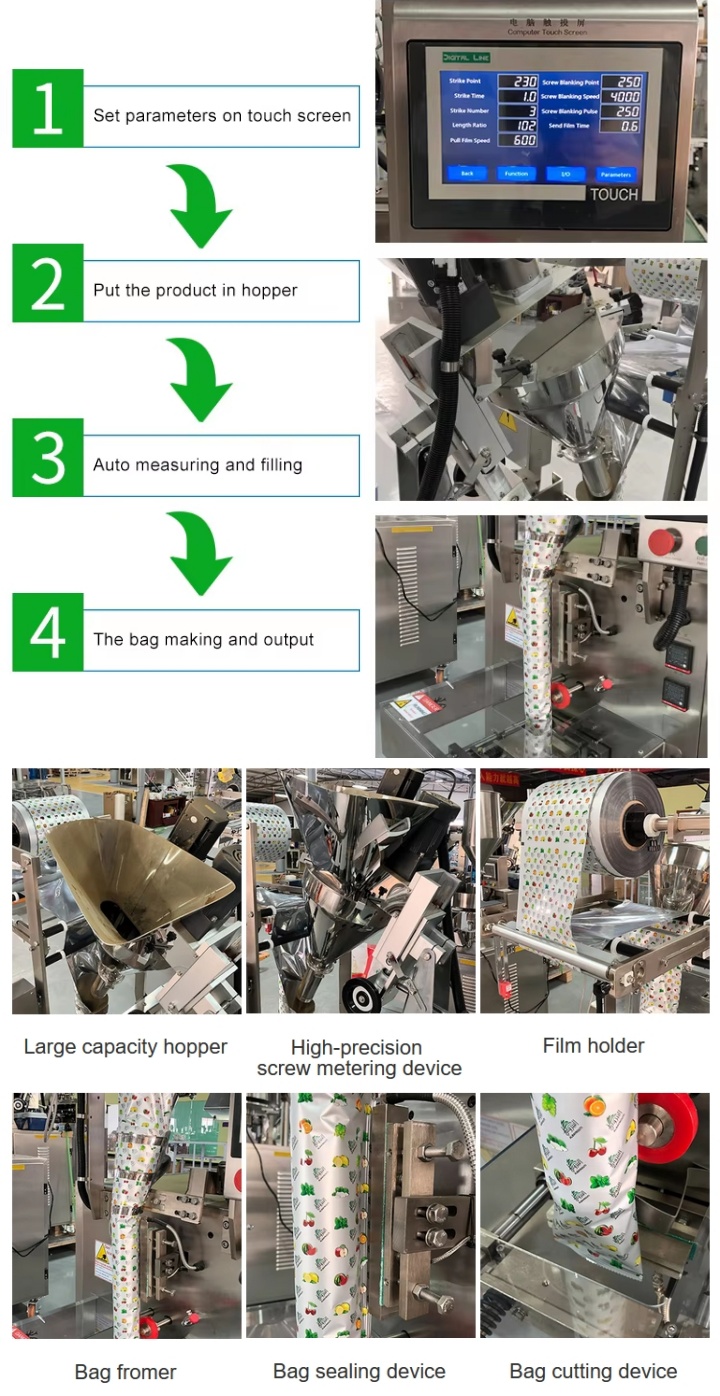

How does the Sachet Packing Machine for Powder work?

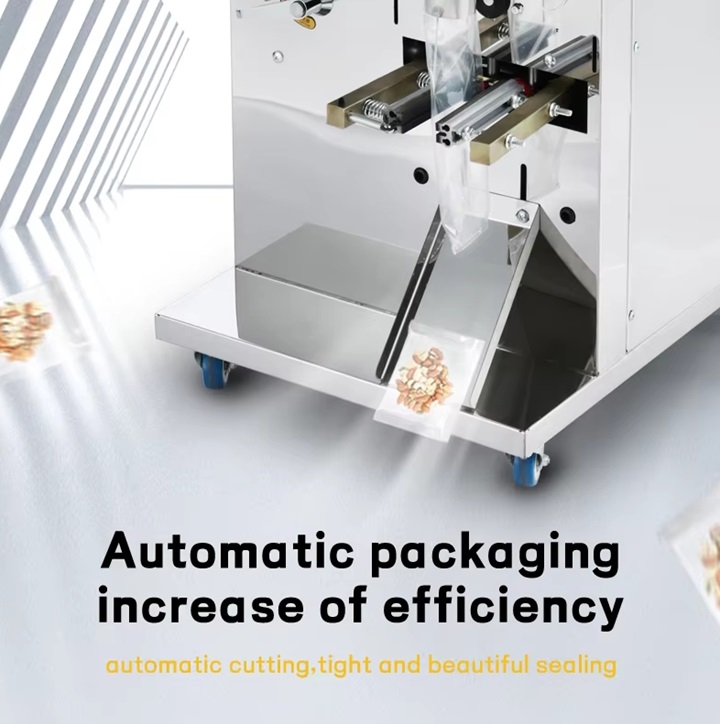

A Sachet Packing Machine for Powder automates the entire process: First, it forms a bag from a roll of film (like plastic or composite material) by folding and heat-sealing the edges. Next, a precision filling system (such as a screw auger or weighing sensor) doses the exact amount of powder into the bag. Then, the machine seals the top with heat or pressure to prevent leaks. Finally, the finished sachet is cut and ejected for collection. Advanced models even include dust control, multi-lane filling, and touchscreen adjustments for different powder types (like flour, spices, or pharmaceuticals). This seamless "form-fill-seal" process ensures speed, accuracy, and minimal waste—key for industries from food to chemicals.

What are the applications of Sachet Packing Machine for Powder?

The Sachet Packing Machine for Powder is suitable for powder, liquid, paste, grain or granular products such as flour, powdered sugar, coffee powder, spice powder, loose powder, blush, pesticide, fertilizer, tablets or capsules. In addition, the powder pouch packaging machine can be customized to make four-side sealed bags, three-side sealed bags, back-sealed capsule bags and special-shaped bags to meet your personalized needs. The sticker packaging can be a serrated edge or a plain cut, or it can have a beautiful-looking shape cut with a tear-type cut. This machine can also make a predetermined number of chain bags.

What are the features of Sachet Packing Machine for Powder?

1. High-speed adjustable packaging

The machine can pack 20-200 bags per minute; the bag length and speed can be digitally adjusted via the touch screen without any mechanical changes.

2. Precision powder filling

Adopt auger or weighing sensor to ensure accuracy (error ±0.2% to ±1%); can handle powders from free-flowing to sticky (such as flour, spices, medicines).

3. Dust-free hygiene

The sealed filling system (such as negative pressure suction) prevents powder from overflowing; stainless steel contact parts meet food/pharmaceutical hygiene standards (compliant with GMP and FDA standards).

4. Intelligent automation

PLC control + touch screen, easy to operate; preset memory function can save more than 10 recipes (such as recipes with different weights/materials)

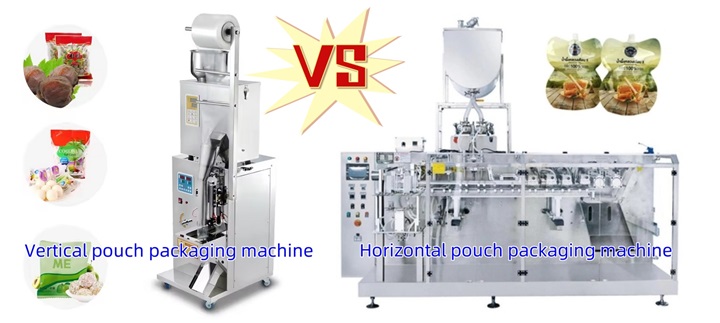

What is the difference between horizontal and vertical Sachet Packing Machine for Powder?

Vertical packaging: Small bag vertical packaging machine works in a vertical direction. Applicable bag types include stand-up bags, three-side sealed bags and four-side sealed bags. Small bag vertical packaging machine is suitable for packaging materials in different forms such as powders, granules, liquids, etc. It has the characteristics of small footprint and easy operation, and is widely used in food, cosmetics, medicine, agriculture and other industries.

Horizontal packaging: Small bag horizontal packaging machine works in a horizontal direction, and applicable bag types include horizontal sealed bags and pillow bags. Small bag horizontal packaging machine is suitable for packaging materials in different forms such as solid materials, strip materials, block materials, etc. It is widely used in food, beverages, daily chemicals, medicine and other industries.

Sachet Packing Machine for Powder Parameters

| MODEL | VFH-320 | VFH-3S-320 | VFH-4S-320 |

| Bag Styles | Pillow Bag | ||

| Bag Length | 30 to 180 mm | 30 to 150 mm | 30 to 150 mm |

| Bag Width | 30 to 135 mm | 25 to 135 mm | 40 to 135 mm |

| Film & Reel | 0.04-0.12 mm (30-120 mic,) Real Max,Dia.400 mm(15.75 " )Real Core Dia.75 mm (2.95 ") | 0.04-0.12 mm (30-120 mic,) Real Max,Dia.400 mm(15.75 " )Real Core Dia.75 mm (2.95 ") | 0.04-0.12 mm (30-120 mic,) Real Max,Dia.400 mm(15.75 " )Real Core Dia.75 mm (2.95 ") |

| Max. Reel Width | 300mm(11.81") | 270mm(10.63”) | 270mm(10.63”) |

| Packing Speed | 40-80 bags/min | 40-80 bags/min | 35-80 bags/min |

| Power & Voltage | 1.35 KW, AC220V/50Hz | 1.2 KW, AC220V/50Hz | 1.8 KW, AC220V/50Hz |

| Dimensions | 650*850*1650mm | 650*850*1650mm | 650*850*1650mm |

| MACHINEWEIGHT | 250 KGS | 250 KGS | 250 KGS |

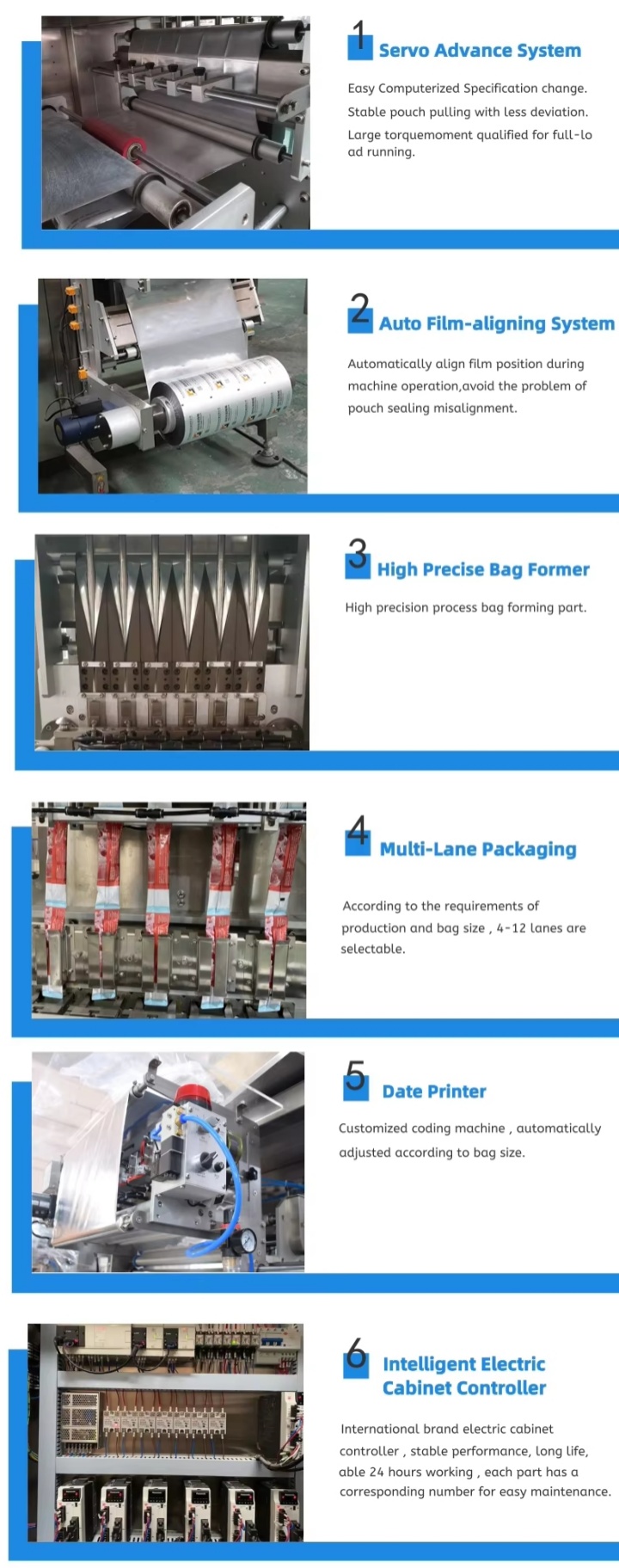

What is the structure of Sachet Packing Machine for Powder?

Powder bag packaging machine usually consists of powder supply system, weighing system, filling system, sealing system and control system.

Sachet Packing Machine for Powder Customer Cases

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| An international sports nutrition brand uses a fully automatic powder pouch packaging machine for single-dose packaging of fitness supplements such as protein powder and BCAA, which is convenient for consumers to carry with them. | 20-50g/bag | 60-80 bags/minute | L100-150mm × W70-100mm | Multi-layer composite film (PET/AL/PE), moisture-proof and anti-oxidation |

| A well-known German coffee brand uses a vertical auger powder packaging machine to produce instant coffee sticks, suitable for the hotel, catering and retail markets. | 2-5g/bag | 100-120 bags/minute | L80-120mm × W50-80mm | Aluminum foil composite film (BOPP/AL/PE), light-blocking and fresh-keeping |

| A pharmaceutical company uses an explosion-proof powder bag packaging machine for precise dosage packaging of antibiotics, Chinese medicine granules and other drugs. | 10g/bag | 40-60 bags/minute | L60-100mm × W40-70mm | Medical grade composite film (PET/PE), in line with FDA standards |

What is the price of a Sachet Packing Machine for Powder?

The price of a Sachet Packing Machine for Powder varies according to various factors, including brand, specifications, production capacity, technical configuration, etc. Generally speaking, the price of an entry-level powder pouch packaging machine is about several thousand dollars to tens of thousands of dollars. The price of a mid-range powder pouch packaging machine may be between tens of thousands of dollars and hundreds of thousands of dollars. The price of a high-end, high-capacity, and technologically advanced powder pouch packaging machine may reach hundreds of thousands of dollars or even higher. The specific price still needs to be specifically inquired and negotiated based on the needs and requirements of the customer and the market supply and demand.

Why choose a Sachet Packing Machine for Powder?

1. Meet the needs of small bag packaging: The small bag packaging machine is suitable for the needs of small bag packaging and can meet the market demand for small packaged products.

2. Improve packaging efficiency: The small bag packaging machine has high-speed continuous packaging capabilities, and can quickly complete operations such as filling, sealing and cutting, thereby improving packaging efficiency.

3. Maintain product quality: The small bag packaging machine can accurately control the filling amount to ensure that the product weight in each small bag is consistent, thereby maintaining the stability of product quality.

4. Reduce packaging material waste: The small bag packaging machine usually has precise metering and adjustment functions, which can adjust the size and capacity of the packaging bag according to the needs of the product, reducing the waste of packaging materials.

How to Select Sachet Packing Machine for Powder?

1. Packaging Speed (Bags/Minute) – Match Your Production Needs

Low-Speed (20-50 bags/min) → Ideal for small businesses, R&D, or low-volume production.

Medium-Speed (50-100 bags/min) → Best for mid-sized food, pharmaceutical, or chemical industries.

High-Speed (100-200+ bags/min) → Required for large-scale manufacturers (e.g., protein powder, instant coffee, detergent).

2. Filling Capacity (Grams per Sachet) – Precision Matters!

Micro Dosing (0.1g-5g) → Used for pharmaceutical powders, spices, or supplements.

Small Portions (5g-50g) → Common in protein powders, instant drinks, or cosmetics.

Bulk Packaging (50g-500g+) → Suitable for detergents, flour, or industrial chemicals.

⚠️ Key Consideration: Machines with servo-driven auger fillers ensure ±1% accuracy—critical for costly powders.

3. Bag Material – Ensure Product Freshness & Durability

| Material Type | Best For | Key Benefits |

| PET/AL/PE (Aluminum Foil) | Coffee, Pharma, High-Moisture Powders | Oxygen & moisture barrier |

| BOPP/PE (Plastic Laminate) | Spices, Protein, Detergents | Cost-effective, printable |

| Paper/Al/PE (Eco-Friendly) | Organic Products, Food | Sustainable, biodegradable |

Must-Have Feature: Ensure the machine supports heat sealing or ultrasonic sealing for airtight packaging.

4. Bag Size & Shape – Customization for Branding

Standard Sizes: 50mm x 80mm (stick packs), 100mm x 150mm (stand-up pouches)

Custom Shapes: 3-side seal, 4-side seal, or doypack (stand-up) sachets

Multi-Lane Filling: For higher output (e.g., 2-4 sachets at once)

Branding Tip: Machines with auto date coding & QR printing enhance traceability.

5. Additional Features for Maximum Efficiency

Touchscreen PLC Control – Easy operation & recipe storage

Gas Flushing (Nitrogen) – Extends shelf life for sensitive powders

CIP (Clean-in-Place) System – Essential for pharma & food-grade compliance

Multi-Language Support – Useful for export-oriented businesses

Wednesday September-03 2025 18:22:51